16

ENG

During cleaning and maintenance work,

make sure the safety instructions set out

on page 14 are complied with.

• If your kitchen hood is made from stainless

steel, use proprietary cleaners mentioned

in the product instructions.

• If your kitchen hood is painted, use

lukewarm water and a neutral soap.

• Never use metallic scourers, nor abrasive

or corrosive products.

• Dry the kitchen hood using a cloth that

does not produce fibres.

To remove the filters from their fittings, press

lightly on the locks and then pull them off.

The metal filters can be cleaned by soaking

them in hot water with neutral detergent until

the fat dissolves and then rinsing them under

the tap or using special anti-grease products.

They can also be washed in a dishwasher. In

this case, it is advisable to stack them

vertically to avoid food residues to stick to

them.

Cleaning in a dishwasher with aggressive

detergents or polish may damage the metallic

surface (blackening it), although this will not

affect its fat retention capacity.

Once clean, leave them to dry off and then fit

them onto the kitchen hood.

Proceed as follows:

• Remove the metal filters.

• Change the broken/burnt out lamp.

Maximum lamp power is 40 W (E-14).

• Fit the metal filters.

Changing light bulbs

Cleaning the metal filters

Cleaning the hood body

Cleaning and maintenance

_________________________________________________________

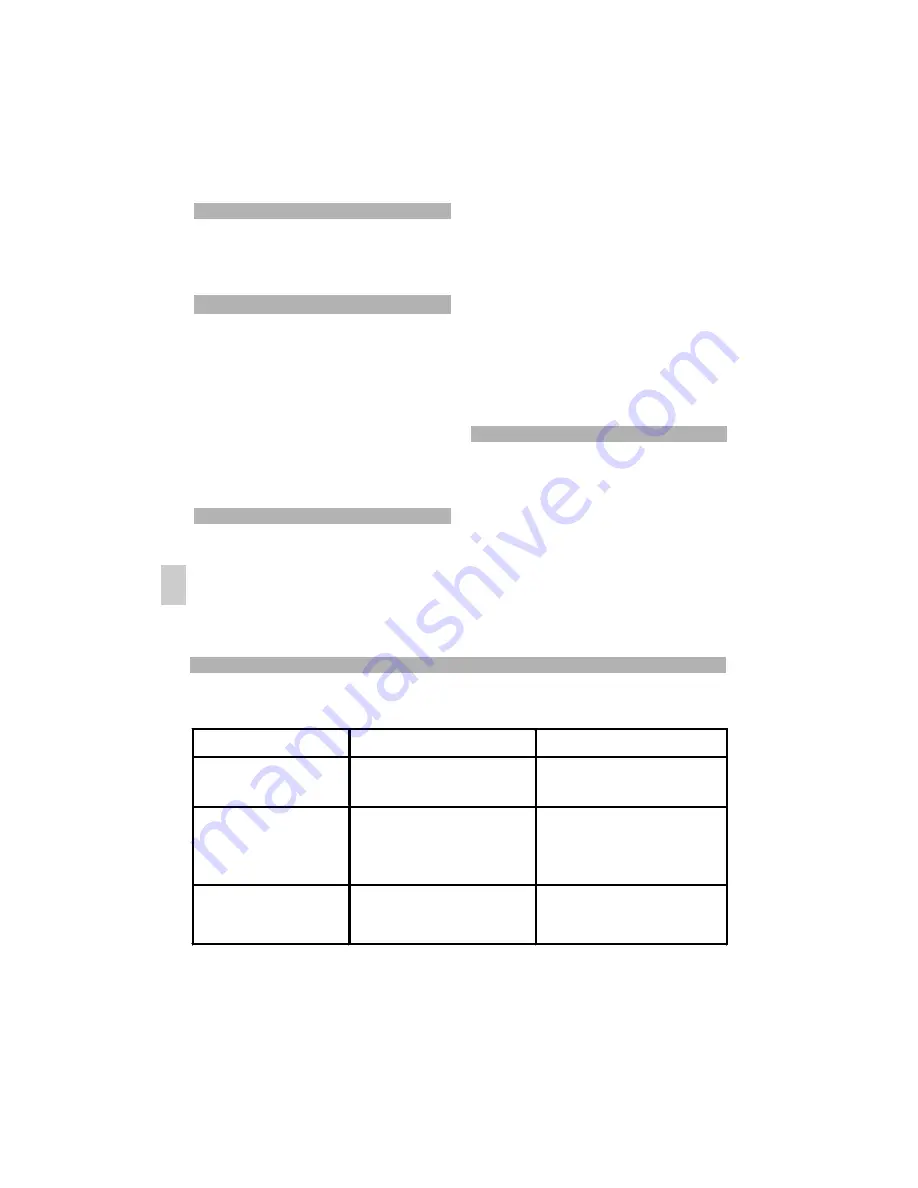

Problem solving

Proceed with the following checks before calling Technical Services:

Problem

Possible cause

Solution

The extractor fan does not work.

The mains cable is not connected to the

network.

There is no current in the network.

Connect mains cable to the network.

Provide current to the network.

The kitchen hood does not extract

sufficiently or vibrates.

Filters are saturated with fat.

Obstruction in the air exit conduct.

Change or clean the active charcoal and/or metal

filters, as the case may be.

Remove the obstruction.

The lamps do not light up.

The lamps are blown.

The lamps are slack.

Change the lamps.

Tighten the lamps.

Summary of Contents for DI 110

Page 7: ...19 ENG FIG 1 FIG 2 ...