18

ENG

1

150/125 mm reduction.

1 Anti-recoil

valve.

2

Support for tubecover.

2

Wall support.

6

Wall plugs (Ø8 x 40).

6

Long bolts (Ø5 x 45).

4

Wall plugs (Ø6 x 30).

4

Long bolts (Ø4 x 30).

2

Ø6.4 x Ø18, washers.

2

Ø6.4 x Ø12, washers.

2

Screws (Ø3.9 x 13).

4

Screws (M4 x 12).

2

Clips.

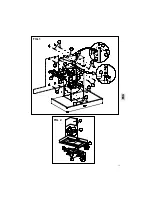

Fig. 1 (Page 19)

On installing the kitchen hood make sure

that the Safety Instructions set out on page

14 are complied with.

To obtain optimum performance, the external

duct must not be more than FOUR METRES

LONG, have no more than two 90° angles and

its diameter must be at least Ø120.

1) Using the attached template, trace and drill

the points for fitting the wall plugs onto the wall

(P) (Ø8 x 40) and (J) (Ø6 x 30).

2) Attach the Supports (O) to the wall using the

long bolts (Q) (Ø5 x 45) and the support (H)

with the long bolts (I) (Ø4 x 30), as in figure 1.

3) Hang the kitchen hood onto the mounted

supports (O). Straighten the appliance by

tightening the long bolts (L) (M4 x 12).

4) Trace the location of the long bolts (S) (Ø5 x

45).

5) Take the kitchen hood off.

6) Drill into the wall and fit the wall plugs (R)

(Ø8 x 40).

7) Hang the kitchen hood; tighten the screws

(M) (M4 x 12) with the washers (A3) (Ø6.4 x

Ø12) and the long bolts (S) (Ø5 x 45) with the

washers (T) (Ø6.4 x Ø18).

8) Mount the tubecovers, attaching the lower

one to the support (H) as per the detail in figure

1. Lift the upper tubecover up to the desired

height and mark its shape on the wall. Remove

the tubecovers.

9) Fit the clips (F) to the support (C).

10) Centre the support (C) around the shape

marked; trace and drill the fixing points for the

wall plugs (E) (Ø6 x 30). Attach the support (C)

with the long bolts (D) (Ø4 x 30).

11) Fit the part (A) if the inner tube (not

supplied) is Ø150 or (A) + (B) if it is Ø120.

12) Attach the inner tube with a clamp (not

supplied) to (A) or (B) as the case may be.

13) Once the inner tube is fitted, fit the lower

tubecover around the extractor fan outlet and

attach the upper tubecover with the screws (G)

(Ø3.9 x 13).

When exterior gas extraction is not possible,

then the kitchen hood may be set to purify the

air by recycling it through active carbon filters.

The active carbon filters have an active life of

between three to six months, depending on

the individual conditions of use. These filters

cannot be washed nor regenerated. They must

be replaced once their useful life comes to an

end.

SET type 1 - Fig. 2 (Page 19)

1) Fit the nut-supports (F) onto the body of the

kitchen hood.

2) Attach the supports (B) with the screws (E)

(M4 x 12) onto the nuts (F).

3) Mount the carbon filters (A) introducing the

anchorages into the grooves of the supports

(B).

4) Remove the tubecovers (H). Fit the diffuser

(C) on to the motor's air outlet vent. Fit the

tubecovers back on (H).

Active charcoal filters (Optional)

Installation

Accessories supplied

Summary of Contents for DI 110

Page 7: ...19 ENG FIG 1 FIG 2 ...