© 2013

400_D - 09/13

24 of 32

Setpoint Operation

Section D

A Setpoint Call is required in order for the control to provide

heat to a setpoint load, such as a spa, pool, or snowmelt

load. This can be done in two ways:

Contact Closure

--------------------------------

--------------------------------

A dry contact or 24 V (ac) signal is applied across the

Setpoint Call terminals on the 400.

tekmarNet

®

Setpoint Control with Sensor

-------

-------

A Setpoint Call is provided through the tekmarNet

®

system. This can be done through the tN4 Expansion

terminals with a setpoint device such as a Setpoint

Control 161.

Once the control registers a Setpoint Call, it will display

the “Setp” icon under Calls in the display.

Note:

Setpoint operation has a fixed priority of on.

Setpoint Operation

-----------------------------

-----------------------------

The control can operate to satisfy the requirements of a

setpoint load in addition to a space heating load and a

DHW load. A setpoint load overrides the current outdoor

reset temperature and WWSD setting in order to provide

heat to the setpoint load.

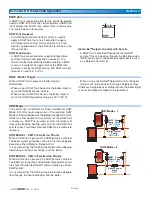

Setpoint Priority

Boiler System

Pump

Setpoint

Pump

Zone

Valve

Setpoint

ON

OFF

OFF

When the control receives a Setpoint Call:

All Boiler zones are turned off.

The boiler will operate to maintain the Setpoint tem-

perature as set in the Adjust menu, or as set on the

tekmarNet

®

Setpoint control if one is being used.

Setp

Calls

It is assumed that the Setpoint pump will provide adequate

flow through the heat exchanger and the boiler.

Setpoint calls will also be responded to when the system

is in

Away

, which can be set using a 479 User Switch.

Setpoint Priority Override

----------------------

----------------------

To prevent the building from cooling off too much or

the possibility of a potential freeze up during setpoint

priority, the control attempts to limit the amount of time

for setpoint priority.

As the outdoor air temperature becomes colder, the length

of time the control provides setpoint priority is reduced.

Once the allowed time for priority has elapsed, the control

will check the space heating target.

If there is a space heating target, the boiler operates at

that target for 15 minutes.

If after 15 minutes there is still a Setpoint Call, the con-

trol will, shut off all boiler heating zones and target the

Setpoint temperature.

Note: It is possible to disable Setpoint Priority by using

a tekmarNet

®

Setpoint control and turning the priority

to Off in the Setpoint control.

•

•

•

•

•

Boiler Operation

Section E

The 400 is able to operate a single 1-stage or 2-stage on-

off boiler or a single modulating boiler as a heat source.

For proper operation of the boiler, the 400 must be the only

control that determines when the boiler is to fire.

*Important note:

The operating control in the boiler, also

known as an aquastat, remains in the burner circuit and acts

as a secondary upper limit on the boiler temperature. The

boiler operator temperature setting can be adjusted above

210°F, which is the fixed Boiler Maximum on the 400.

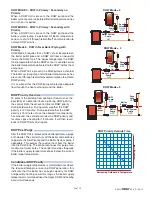

Boiler Target Temperature

----------------------

----------------------

The boiler target temperature is the temperature which

the control is trying to operate the boiler at. There are

four items that determine the boiler target temperature:

Boiler Call

DHW Call

Setpoint Call

If the control receives more than one call for heat at the

same time, it will operate the boiler at the highest of the

four calls.

•

•

•

The control displays the temperature that it is currently

trying to maintain as the boiler supply temperature in the

View menu. If the control does not presently have a call for

heat, it does not show a boiler target temperature. Instead,

‘– – –’ is displayed on the LCD.

Boiler Minimum

--------------------------------

--------------------------------

When operating non-condensing boilers, it is important

to prevent cool water from returning to the boiler. Cold

return temperatures create flue gas condensation, which

if left too long, can severely damage the boiler.

The 400 protects the boiler through the Boiler Minimum

setting. The boiler minimum is the lowest temperature that

the control is allowed to use as a boiler target temperature.

If the boiler is operating at the boiler minimum temperature,

the “MIN” segment is turned on in the display when viewing

either the boiler supply temperature or the boiler target

temperature.