© 2013

400_D - 09/13

25 of 32

Boiler Maximum

--------------------------------

--------------------------------

The 400 will operate the boiler so that the boiler

supply temperature will never exceed 210°F (99.0°C).

The highest allowed boiler target is the boiler design

tempe 10°F (5.5°C).

Boiler Type

-------------------------------------

-------------------------------------

The 400 can operate either of the following types of

boilers:

One single-stage on-off boiler

One two-stage on-off boiler

Modulating boiler using a 0-10 V (dc) signal

Modulating boiler using a 4-20 mA signal

tekmar EMS signal (for use with multiple boiler

stagers)

EMS signal for Viessmann modulating boilers

On-Off Operation

-------------------------------

-------------------------------

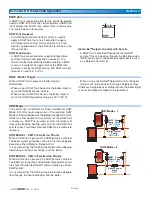

The 400 operates a single hot-water on-off boiler to

maintain the boiler target within a differential. The boiler

target is the average temperature and the boiler supply

temperature can fluctuate by 1/2 of the differential above

and below of the boiler target.

Modulation Boiler Operation

-------------------

-------------------

The 400 can operate a single hot-water modulating

boiler using the Mod dc/mA output and the Boiler Stage

contact. Not all boilers require the use of the Boiler

Stage contact.

The control operates the boiler by first switching the boiler

stage contact to allow the modulating boiler to go through

the ignition sequence (the boiler stage contact may not

be required on all modulating boilers). A 0-10 V (dc) or 4-

20 mA analog signal is then used to modulate the boiler

firing rate starting from 50% (5 V (dc) or 12 mA signal) for

30 seconds.

After the 30 second delay has elapsed, the control will

then allow the boiler to modulate down to the minimum

modulation setting and hold it there for the Modulation Delay

time setting. The Modulation Delay setting is determined

by the boiler manufacturer. It is the amount of time that

the burner must operate before the internal boiler control

allows an external signal to operate the burner.

After the Modulation Delay has elapsed, the control uses

PID logic to change the boiler firing rate signal in order

to satisfy the boiler target temperature. When the firing

rate signal is reduced down to the Minimum Modulating

setting and the boiler supply temperature exceeds the

boiler target by 1/2 of the differential, the control will shut

off the burner.

•

•

•

•

•

•

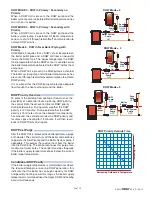

Minimum Modulation

The Minimum Modulation is the lowest signal the control

can send to modulate the boiler. This operates the boiler

at low fire.

Refer to the boiler manufacturer’s literature to deter-

mine the minimum output voltage V (dc) or current

(mA) that the boiler will successfully operate at.

For 0-10 V (dc):

Minimum Modulation =

Boiler’s Minimum Input Signal x 100%

10 V (dc)

For 4-20 mA:

Minimum Modulation =

Boiler’s Minimum Input Signal - 4mA x 100%

16 mA

Example:

A boiler requires a 1.8 V (dc) signal to fire the boiler at

low fire. The boiler can be modulated to 10 V (dc) where

it reaches high fire.

Minimum Modulation = 1.8 V x 100% = 18%

10 V

1.8 V (dc)

10 V (dc)

Control Rang

e

Boiler Rang

e

0 Vdc

18%

tekmar EMS Signal Operation

The 400 can provide a 0-10 V (dc) signal proportional to

the boiler target which is compatible with tekmar Boiler

Staging controls that accept an EMS input.

To use the tekmar EMS signal operation, the Boil Type

setting in the Adjust menu must be set to EMS1.

Viessmann EMS Signal

The 400 has a special 0-10 V (dc) signal proportional to

the boiler target that is designed to be compatible with

Viessmann Open Therm 0-10 V (dc) inputs.

To use the Viessmann EMS signal operation, the Boil

Type setting in the Adjust menu must be set to EMS2.

The signal is 0 V (dc) when the boiler is off. The voltage

is 2.2 V (dc) to provide a boiler target of 81°F (27°C),

up to maximum of 10 V (dc) to provide a boiler target of

176°F (80°C).

•

•

•