© 2013

400_D - 09/13

6 of 32

External Power Supply

It is strongly recommended that a transformer with an in-line

fuse be used in order to protect the transformer from high

currents. The tekmar Transformer 009 includes a fuse.

Connect the 24 V (ac) leads from the transformer to the

C and R terminals marked “Input Power” on the 400.

tN2 Thermostats

The 400 is designed to operate with tekmarNet

®

2 Thermostats.

They provide the heating and cooling control for each zone,

and communicate with any other tekmarNet

®

device on

the system.

Connect the tN2 terminals from each thermostat to the

corresponding tN2 terminals for each zone on the 400.

Zone Valves

Wire the zone valves to the C and Vlv terminals on the

400.

End switches on zone valves are not required when

using the 400.

tN4 Boiler Expansion Terminals

The 400 uses the Boiler Expansion tN4 and C terminals to

communicate with additional thermostats, setpoint controls,

and other tekmarNet

®

devices.

Connect the tN4 and C Boil Exp. terminals on the 400

to the corresponding tN4 and C Expansion terminals

of the additional external device.

•

•

•

•

•

Low Voltage Wiring

-----------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

Ensure that the pump wires are neatly tucked inside

the electrical box.

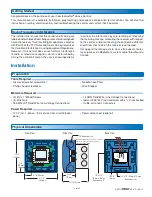

Using 2 of the 4 holes in the back of the enclosure, se-

curely fasten it to the electrical junction box with 2 #10

screws as shown in Figure 5.

•

•

Install The Enclosure

---------------------------------------------------------------------------------

---------------------------------------------------------------------------------

Figure 5

Domestic Hot Water (DHW) or Setpoint Call

When the control receives a DHW Call or Setpoint Call for

heat it will override Outdoor Reset and Indoor Feedback

and operate the boiler to heat the DHW tank or the Setpoint

equipment.

To create a DHW call, wire a dry contact OR apply

24 V (ac) to the DHW call terminals.

To create a Setpoint call, wire a dry contact OR apply

24 V (ac) to the Setpoint call terminals.

Wiring the Boiler

The 400 can operate a single modulating boiler, single

on-off, or a single two-stage on-off boiler.

On/Off Boiler

Connect the Boiler Stage 1 terminals on the 400 to the

T-T (or R-W) terminals on the boiler.

If required, connect the Boiler Stage 2 terminals on the

400 to the second stage T-T (or R-W) terminals on the

boiler.

Modulating Boiler

Wire the Mod (dc/mA) positive (+) and negative (-) ter-

minals on the 400 to the input signal terminals on the

boiler. Correct polarity of the wires is important.

In some cases, the modulating boiler also requires

contact closure on the T-T terminals to fire the boiler. If

required, connect the Boiler Stage 1 terminals on the

400 to the T-T (or R-W) terminals on the boiler.

•

•

•

•

•

•

115 V (ac)

L

N

G

Boil

DHW

to pump grounds

N

L

Boil System Pump

DHW Pump

Pump Power L

Strip wires

1/2 inch (13 mm).

Installed wires are

not removable.

12-18 AWG

(red)

(black)

(black)

Rear Line Voltage Wiring Diagram

--------------------------------------------------------------------

--------------------------------------------------------------------