Maintaining the Nova 3000

General Maintenance

Interval

Maintenance

After each use

Clean the work area and lathe. Vacuum scraps and dust from the

inside the headstock, between the lathe bed rails, and under the

toolslide and tailstock.

Monthly

Wax exposed cast iron parts with a good quality paste wax,

especially the bed rails. Buff out the wax thoroughly.

Check tightness of nuts and bolts; especially the set screws on the

motor pulley and headstock pulley, and the lathe mounting bolts.

Lubricate, with one or two drops of light-weight oil, the tailstock quill

threads, index pin shaft, and the toolslide camshaft (remove plastic

plugs) and toolslide front camshaft bore.

6 Months

Grease tailstock quill threads. Turn the handwheel so the quill

threads are exposed, apply grease to the threads, crank the

handwheel back and forth to work in the grease, wipe off any

excess.

Lubricate the tailstock slot with one or two drops of light-weight oil.

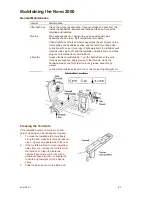

Cleaning the Toolslide

If the toolslide becomes hard to move and

adjust, cleaning and lubricating are required.

1.

To make the toolslide slide more freely

along the bed, make sure the bed rails are

clean. Apply some paste wax to the rails.

2.

If the toolslide is hard to move towards or

away from you, remove the toolslide from

the lathe bed. Clean the toolslide

camshaft (round eccentric rod) with a

petroleum-based solvent. Lubricate the

rod with a light-weight oil or a silicone

spray.

3.

Slide the base back onto the lathe bed.

92-0106-017

21