30

2.

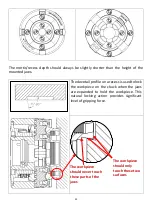

Measure the axial runout of

the spindle itself by:

Locate the DTI on the front

face of the spindle as shown on

the image.

Spin the lathe by hand.

The runout measurement

should be ranging between:

-0.02mm ~ +0.02mm

(-0.00079 ~ +0.00079in)

Any reading exceeding this

value will be exceeding the

standard tolerances.

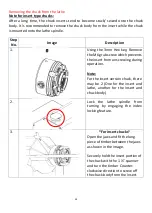

Chuck Inspection

Firstly, inspect the lathe spindle threads for any buildup of debris or any damage.

1.

Thoroughly clean the excessive debris is identified on the lathe spindle

2.

Contact the local machining shop to chase the spindle thread

Secondly, mount the chuck correctly according to instructions on the manual.

1.

If the chuck is an insert model, ensure the insert

is bottomed out on the chuck body before

mounting on the lathe.

2.

For Both Insert & Direct Thread model: Wind the

chuck onto the lathe spindle until the chuck

comes firmly in contact with the bearing/spindle

shoulder with no gaps around it.

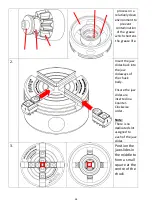

3.

Place red thread protector washer into the M6

Threaded hole. Then wind the M6 grub screw in

position and tighten with M3 Hex head wrench

(provided) to prevent the chuck from loosening

on lathe spindle.