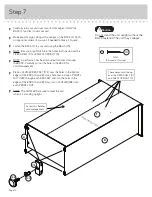

Step 7

Page 12

å

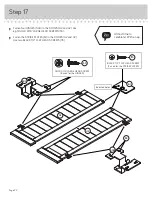

Carefully turn your unit over onto its front edges. Unfold the

BACK (F) and lay it over your unit.

å

Make equal margins along all four edges of the BACK (F). Push

on opposite corners of your unit if needed to make it "square".

å

Fasten the BACK (F) to your unit using the NAILS (1N).

å

NOTE: Be sure to tap NAILS into the holes that line up over the

FIXED SHELF (D) and SHELF UPRIGHT (N).

å

NOTE: A perforation has been provided for access through

the BACK. Carefully cut out the hole in the BACK for

cord management.

å

Place a LEVELER BRACKET (17E) over the holes in the bottom

edges of the ENDS (A and B). Use a hammer to drive a PROPEL

NUT (14M) through each BRACKET and into the holes in the

edges of the ENDS (A and B). Now, turn a LEVELER (18E) into

each PROPEL NUT.

å

NOTE: The LEVELERS are used to level the unit

when it is standing upright.

Do not stand the unit upright without the

BACK fastened. The unit may collapse.

Caution

Unfi

nished sur

face

A

B

F

14M

18E

17E

These holes must line up

over the FIXED SHELF (D)

and SHELF UPRIGHT (N).

NAIL

(46 used in this step)

1N

Cut out this hole for

cord management.