å

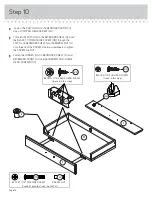

Fasten the RIGHT END (A) to the TOP (D). Fasten two

HIDDEN CAMS.

å

Fasten the RIGHT END (A) to the BRACE (G). Tighten the

HIDDEN CAM.

å

NOTE: Be sure the PIN in the BRACE inserts into the hole

in the END.

å

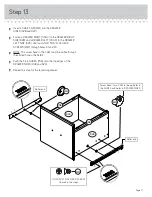

Fasten the BASE (R) to the RIGHT END (A) and UPRIGHT (C).

Use four BLACK 9/16" LARGE HEAD SCREWS (TT).

Step 6

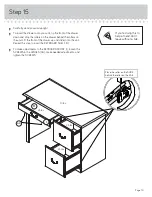

Arrow

Minimum

190 degrees

Maximum

210 degrees

A

G

R

C

Curved edge

BLACK 9/16" LARGE HEAD SCREW

(4 used in this step)

TT

Page 10

D