Step

Page 17

Step 12

å

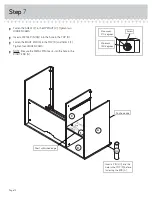

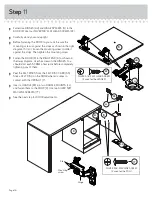

Refer to the enlarged diagram to identify the parts on

the HINGES.

å

The DOORS may need some adjustments. Follow the text

below to make needed adjustments.

å

DOOR ADJUSTMENTS:

To adjust the DOORS from side to side (horizontal) turn the

adjusting screw in or out.

å

To adjust the DOORS up and down (vertical), loosen both

vertical adjustment screws. Move the DOORS up or down to the

desired location. Tighten the screws after making adjustments.

å

To adjust the DOORS in or out (depth), loosen the mounting

screw one turn and move the DOORS in or out, as needed.

Tighten the mounting screw after making adjustments.

Adjusting screw (horizontal)

Mounting screw (depth)

(vertical adjustment)

Hey! It's starting to look

like something!