Reviews:

No comments

Related manuals for 5412314

Cindy

Brand: Naomi Home Pages: 17

BOX

Brand: pakoworld Pages: 2

Avila

Brand: Madison Park Pages: 3

Telos

Brand: NATHAN JAMES Pages: 26

Top Art K-14041

Brand: Kohler Pages: 16

83801-03-01

Brand: Naomi Kids Pages: 10

9002730586671

Brand: Pessotto Pages: 34

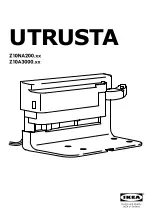

UTRUSTA Z10NA200 Series

Brand: IKEA Pages: 8

Vermont 03VER0808-V1

Brand: Mercia Garden Products Pages: 8

Mia Wide Sideboard

Brand: BROSA Pages: 5

Neo-Ray 752

Brand: Cooper Lighting Pages: 1

C580LP

Brand: RealFlame Pages: 54

183-W5A-DT1-V1-ST

Brand: Pacific Casual Pages: 4

511115

Brand: SilverFox Pages: 3

RACK RETRO RIO

Brand: Olivar Pages: 4

272-1799

Brand: Backyard Creations Pages: 6

AF44JAMET

Brand: Walker Edison Pages: 12

BU58FR2DD

Brand: Walker Edison Pages: 45