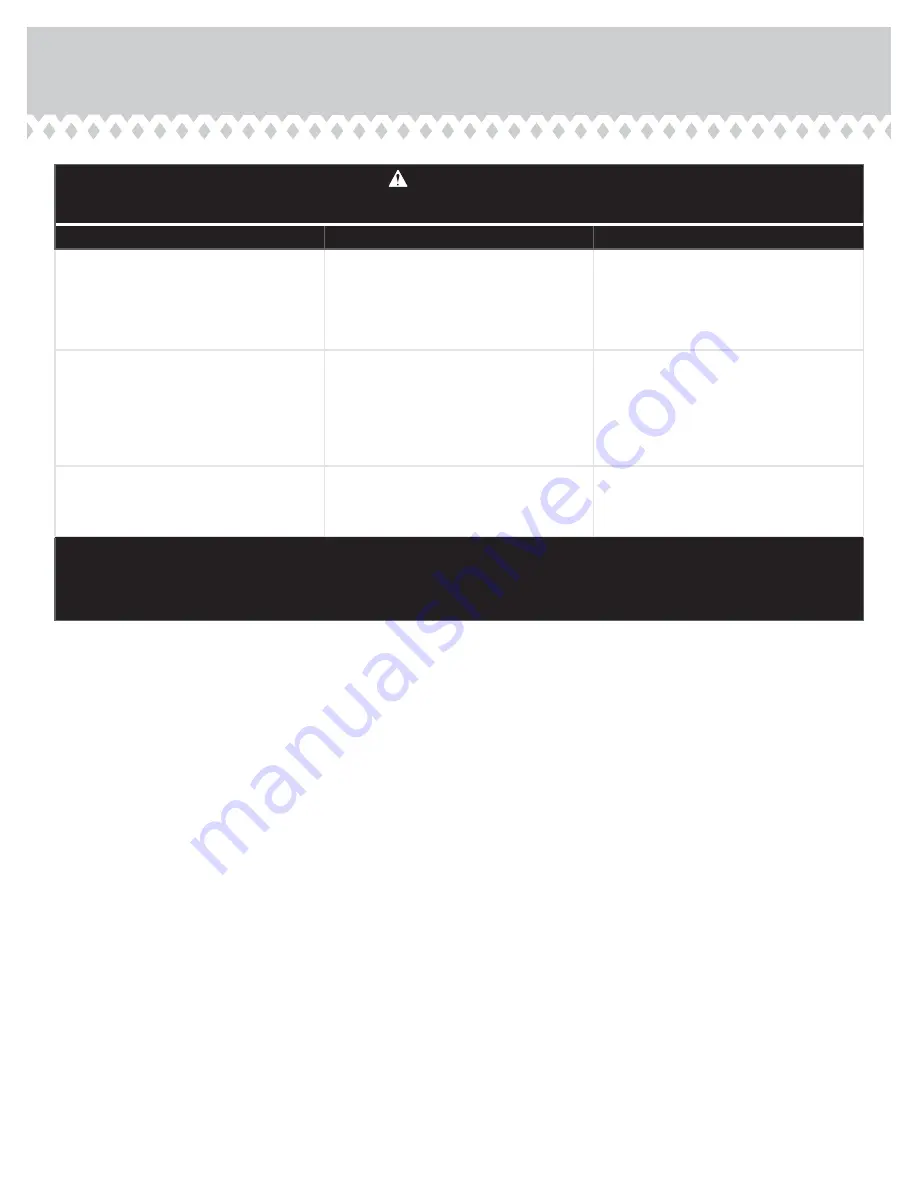

WARNING

Please use your furniture correctly and safely. Improper use can cause safety hazards,

or damage to your furniture or household items.

Carefully read the following chart.

Look out for:

What can happen:

How to avoid the problem:

• Overloaded shelves and drawers.

• Improper loading can cause the product

to be top-heavy.

• Risk of injury.

• Top-heavy furniture can tip over.

• Overloaded shelves and drawers can

break.

• Never exceed the weight limits shown in

the instructions.

• Work from bottom to top when loading

shelves and drawers. Place the heavier

items on the lower shelves or in lower

drawers.

• Improperly moving furniture that is not

designed and equipped with casters.

• Furniture can tip over or break if

improperly moved.

• Physical injury. Furniture can be very

heavy.

• Breakage of tops - particularly with

double pedestal furniture (drawers at both

ends).

• Unload shelves and drawers from top to

bottom before moving the unit.

• Do not push furniture, especially on a

carpeted fl oor. Have a friend help you lift

the item and set it in place.

• Provide support to the center section of

the top when lifting the furniture.

• Placing TVs on furniture items that are

not designed to support a television is

hazardous.

• Risk of injury or death. TVs can be very

heavy. Plus the weight and location of the

picture tube tends to make TVs unbalanced

and prone to tipping forward.

• This product is not designed to support a

television.