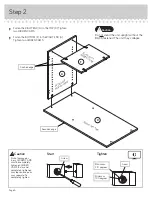

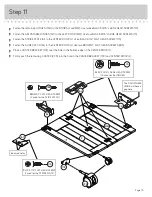

Step 1

å

Assemble your unit on a carpeted fl oor or on the empty

carton to avoid scratching your unit or the fl oor.

å

Push fourteen HIDDEN CAMS (1F) into the ENDS (A and B),

UPRIGHT (C2), BOTTOM (F), MODESTY PANEL (G2),

and SHELF (H2). Then, insert the metal end of a

CAM DOWEL (2F) into each HIDDEN CAM.

(14 used)

Arrow

1F

2F

Insert the metal end of the CAM

DOWEL into the HIDDEN CAM.

Arrow

Do not tighten the HIDDEN CAMS in this step.

C2

A

B

F

H2

G2

Page 5