Step 14

å

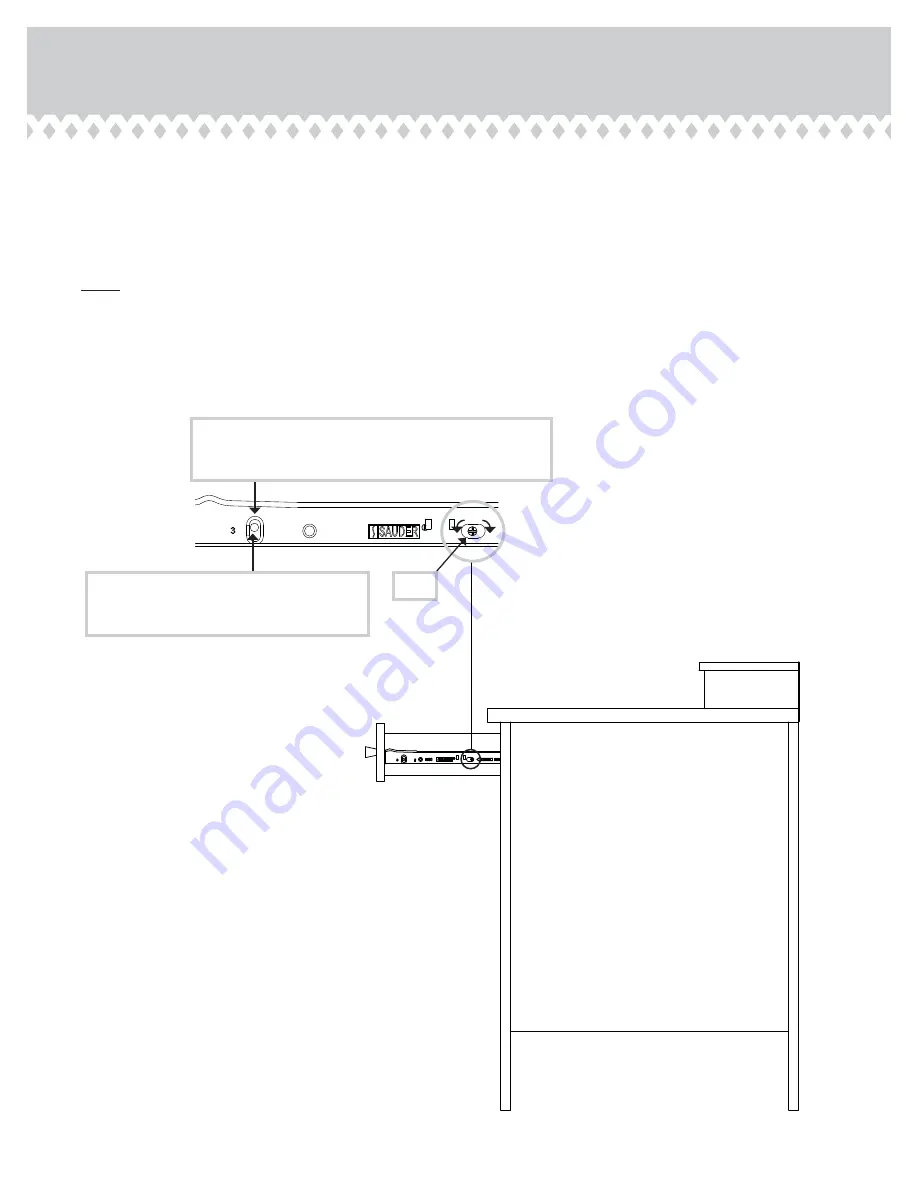

To make adjustments to the drawers, loosen SCREW #3 in the SLIDES a 1/4 turn, then turn the CAM

clockwise or counter-clockwise. Notice how the drawer raises or lowers as you turn the CAM. The

higher the screw in the oblong hole, the higher your drawer front will be. The lower the screw, the

lower the drawer front. By adjusting the drawers this way, it will help the DRAWER FRONTS line up

better when closed. Tighten the SCREW when fi nished with adjustments.

å

NOTE: Please read the back pages of the instruction booklet for important safety information.

å

This completes assembly. Clean with your favorite furniture polish or a damp cloth. Wipe dry.

Page 18

The higher the screw in the oblong hole, the

higher your drawer front will be. The lower the

screw, the lower the drawer front.

Loosen screw #3 a 1/4 turn, turn the cam a 1/4 turn

maximum in both the clockwise and counter-clockwise

directions to make adjustments, and then tighten screw #3.

Cam