å

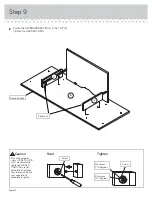

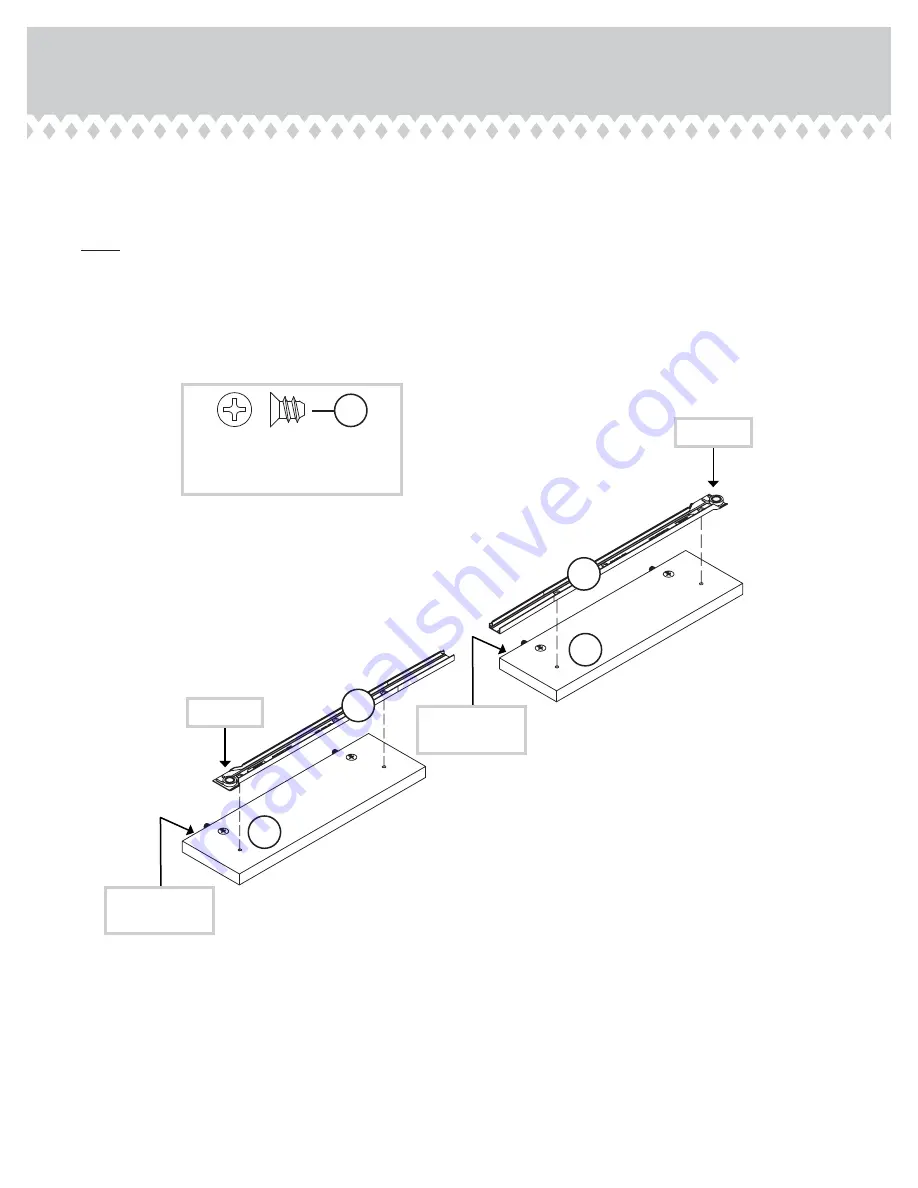

Fasten the BLACK CABINET RAILS (AA and BB) to the

KEYBOARD BRACES (J). Use four GOLD 5/16" FLAT

HEAD SCREWS (3S).

å

NOTE: The CABINET RAILS are marked "CABINET

RIGHT" and "CABINET LEFT" for easy identifi cation.

Step 4

Page 9

J

J

BB

AA

Roller end

Roller end

Sur

face with

HIDDEN CAMS

Sur

face with

HIDDEN CAMS

Edge with

CAM DOWELS

Edge with

CAM DOWELS

GOLD 5/16" FLAT HEAD SCREW

(4 used in this step)

3S