å

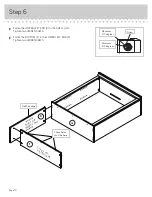

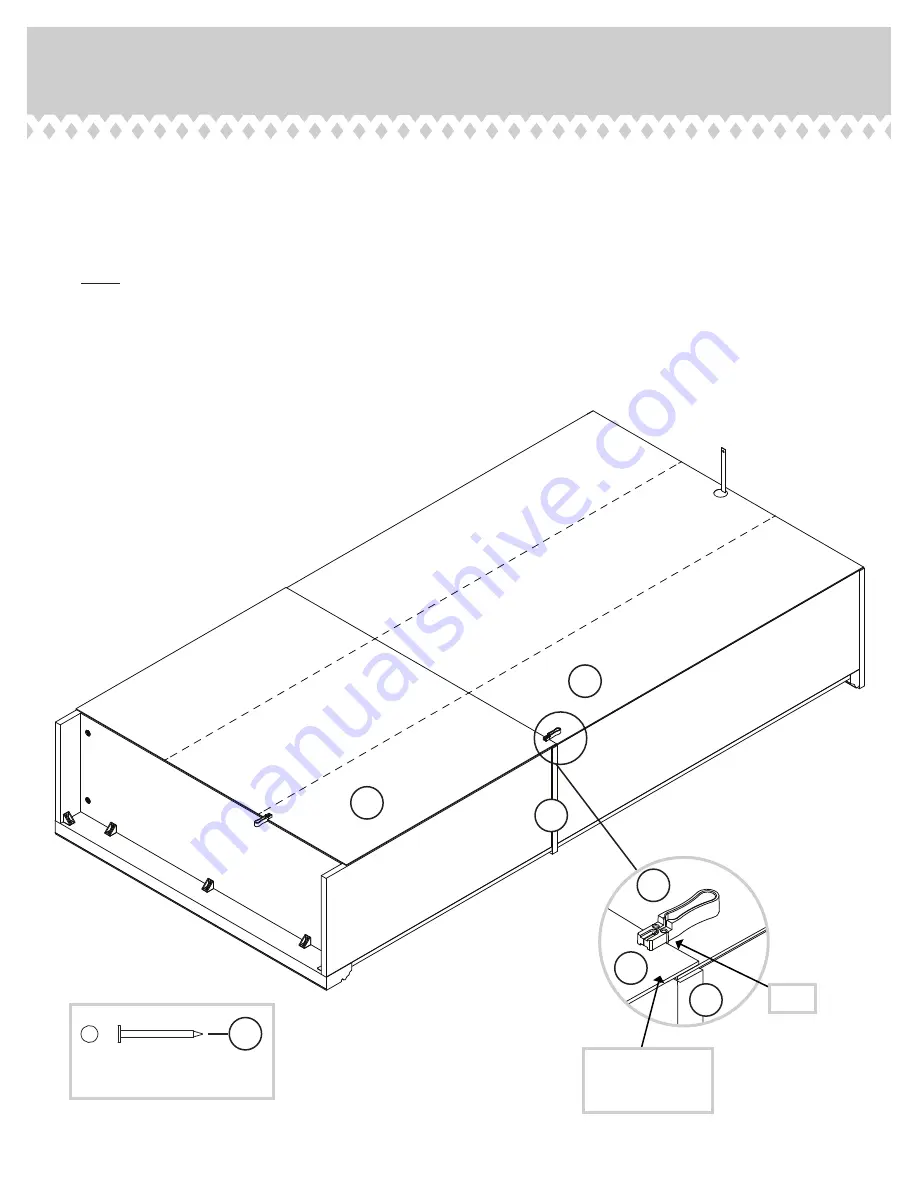

Position the BACK (I) over the lower portion of your unit, making equal margins along the bottom

and side edges.

å

Fasten the BACK (I) to the bottom and side edges of your unit using the NAILS (1N) using the Nail

Holder tool as shown in the previous step.

å

NOTE: The BACK (I) will overlap the LARGE BACK (H2) as shown in the enlarged diagram.

å

Fasten the BACK and LARGE BACK to the SHELF (G2) using the remaining NAILS (1N). by

following the enlarged diagram below.

å

Diagram: Place the bead of the Nail Holder down onto the LARGE BACK (H2) and BACK (I). Place

a NAIL into the nail slot of the Nail Holder. Tap the nail through the BACKS (H2 and I). Repeat this to

tap the remaining NAILS on the top edge of the BACK (I).

Step 11

I

Unfi

nished

sur

face

H2

I

G2

The BACK (I)

overlaps the

LARGE BACK (H2).

Bead

H2

NAIL

(31 used in this step)

1N

Page 15

G2