å

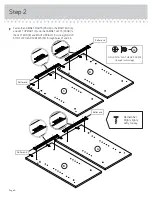

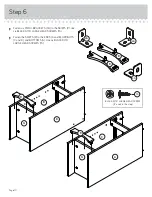

Insert four METAL PINS (1R) into the short edges of the

BRACES (Q).

å

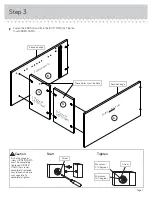

Fasten the BRACES (Q) to the ENDS (A and B). Tighten

two HIDDEN CAMS.

å

NOTE: Be sure the PINS in the BRACES insert into the

holes in the ENDS.

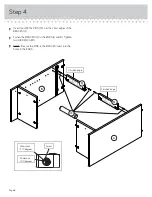

Step 4

Page 8

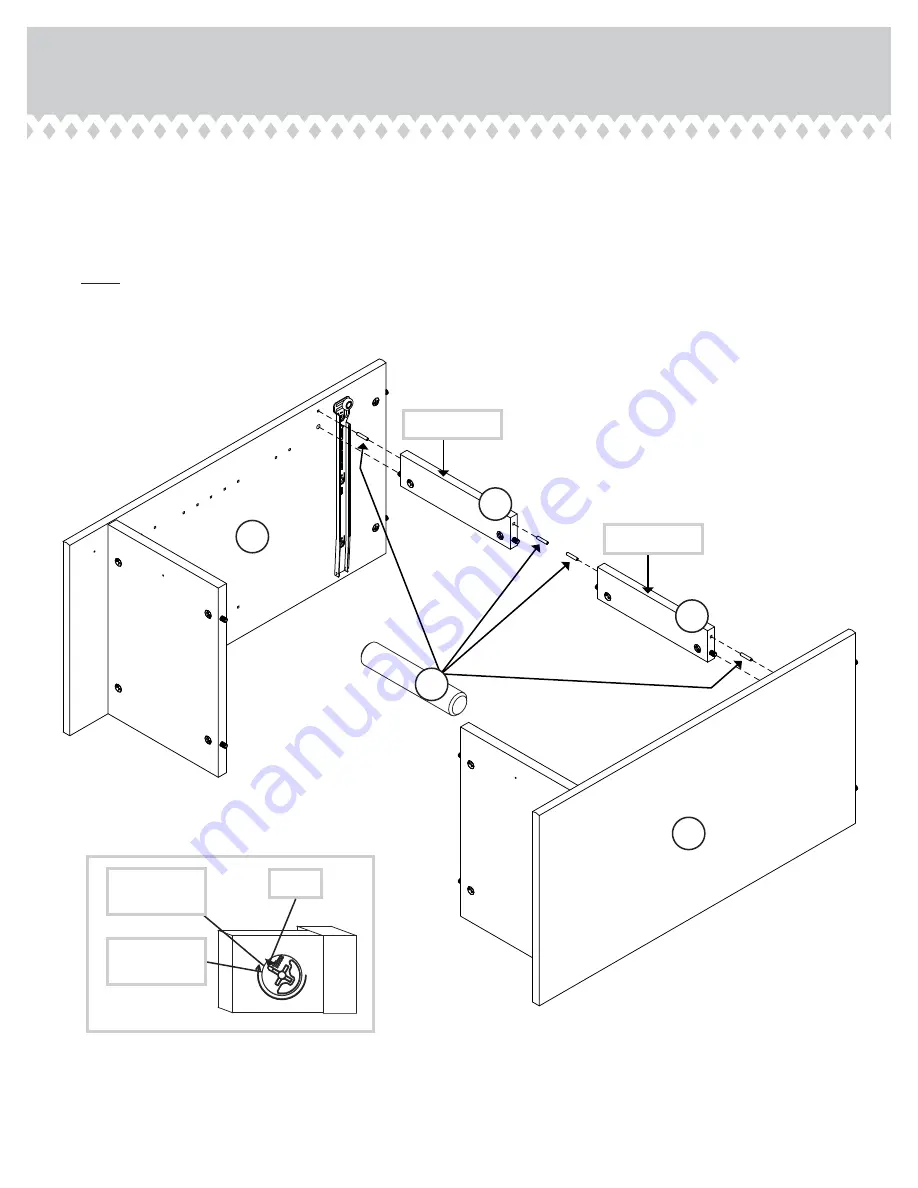

1R

A

B

Sur

face with

HIDDEN CAMS

Sur

face with

HIDDEN CAMS

Q

Q

Arrow

Minimum

190 degrees

Maximum

210 degrees

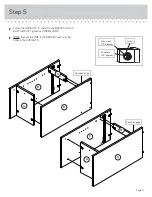

Finished edge

Finished edge