Table of Contents

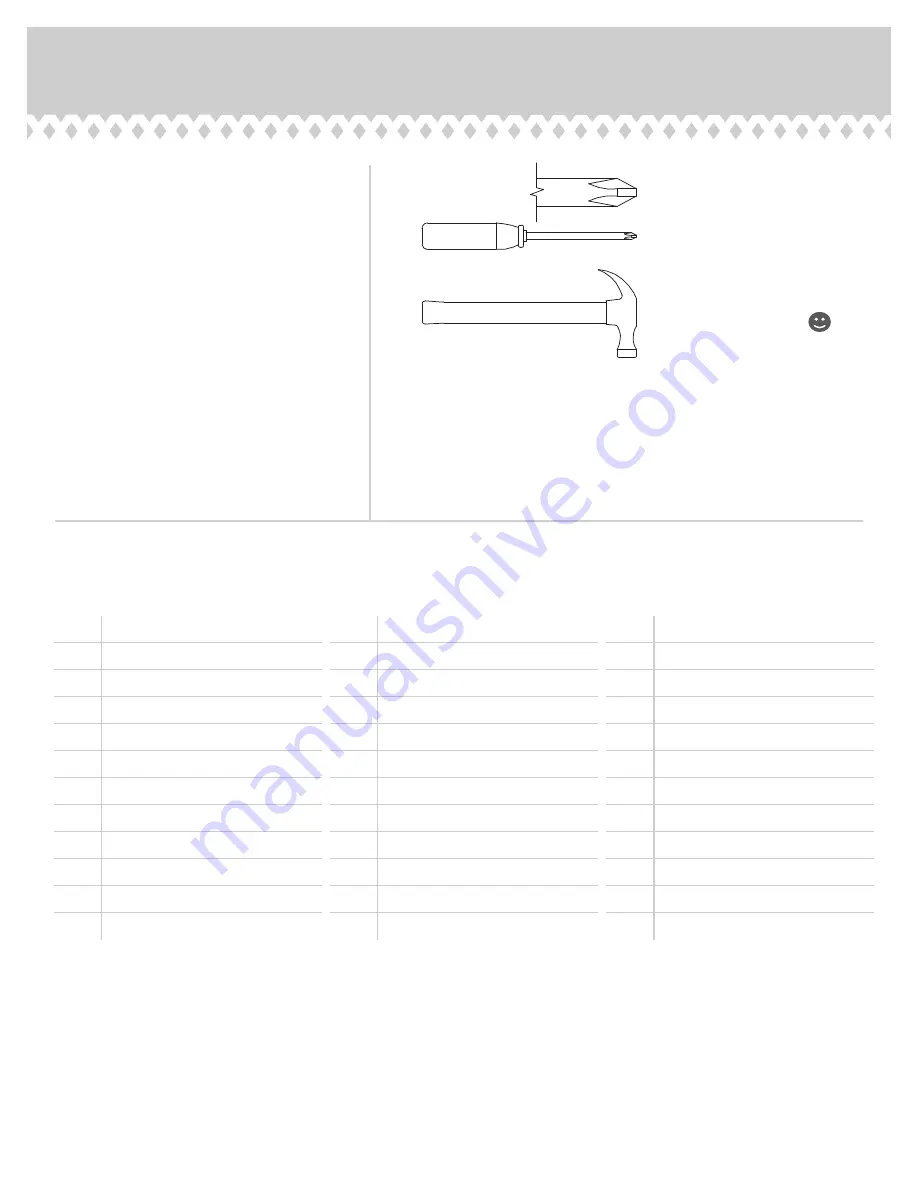

Assembly Tools Required

Part Identifi cation

Hardware Identifi cation

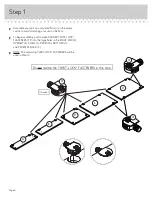

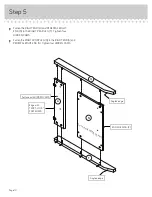

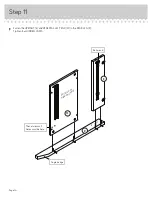

Assembly Steps

Français

Español

Safety

Warranty

Hammer

Not actual size

No. 2 Phillips Screwdriver

Tip Shown Actual Size

2-3

4-5

6-38

39-43

44-48

49-50

51

A

RIGHT END (1)

B

LEFT END (1)

C

TOP (1)

D

LIFT TOP (1)

D14

LARGE RIGHT DRAWER SIDE (1)

D15

LARGE LEFT DRAWER SIDE (1)

D20

SMALL RIGHT DRAWER SIDE (1)

D21

SMALL LEFT DRAWER SIDE (1)

D74

SMALL DRAWER BACK (1)

D78

LARGE DRAWER BACK (1)

D716 DRAWER BOTTOM (2)

E

UPRIGHT (1)

F

LARGE BOTTOM (1)

G

BACK STRETCHER (1)

H

STRETCHER (1)

I

LONG BACK (1)

J

SMALL BACK (1)

K

FRONT (1)

L

SHELF (1)

M

PEDESTAL LEFT END (1)

N

PEDESTAL RIGHT END (1)

O

FRONT LEG (1)

P

LEFT FRONT LEG (1)

Q

RIGHT FRONT LEG (1)

R

REAR LEG (1)

S

LEFT REAR LEG (1)

T

RIGHT REAR LEG (1)

U

PEDESTAL BOTTOM (1)

V

PEDESTAL BACK (1)

W

LARGE DRAWER BOX FRONT (1)

X

LIFT TOP STRETCHER (1)

Y

SMALL DRAWER BOX FRONT (1)

Z

END MOLDING (1)

AA

SMALL UPRIGHT (1)

BB

LARGE DRAWER FRONT (1)

CC

SMALL DRAWER FRONT (1)

Page 2