å

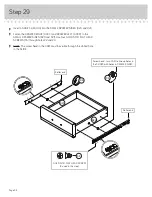

Insert a SLIDE CAM (10A) into the LARGE DRAWER SIDES (D14 and D15).

å

Fasten the EXTENSION SLIDES (35MC) to the LARGE DRAWER SIDES (D14 and D15).

Use four GOLD 5/16" FLAT HEAD SCREWS (3S) through holes #1 and #3.

å

NOTE: The screw head in the CAM must be visible through the slotted hole in the SLIDE.

Step 28

Page 33

Open end

Screw head - turn CAM to line up holes in

the SLIDES with holes in DRAWER SIDES

1

2

3

10A

10A

GOLD 5/16" FLAT HEAD SCREW

(4 used in this step)

3S

1

2

3

Open end

D14

D15