å

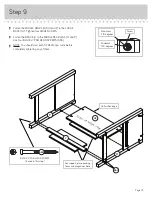

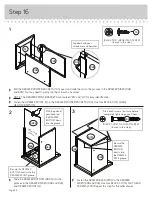

Fasten the MIDDLE REAR LEGS (O and P) to the LARGE

BACK (H2). Tighten four HIDDEN CAMS.

å

Fasten the BRACE (J) to the MIDDLE REAR LEGS (O and P).

Use four BLACK 2" PAN HEAD SCREWS (66S).

å

NOTE: You should start each SCREW a few turns before

completely tightening any of them.

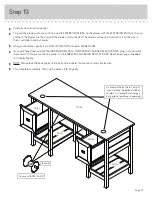

Step 9

Page 13

Arrow

Minimum

190 degrees

Maximum

210 degrees

Sur

face with HIDDEN CAMS

O

P

J

H2

Unfi nished edge

66S

BLACK 2" PAN HEAD SCREW

(4 used in this step)

66S

For support, place packing

foam and magazines here.