å

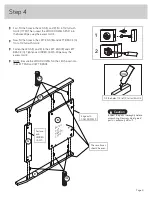

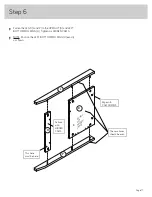

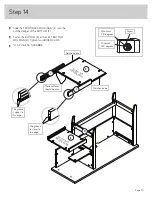

Carefully fl ip the UPRIGHT (D) over.

å

Fasten two EXTENSION BRACKETS (43G) to the UPRIGHT (D). Use four

BLACK 9/16" LARGE HEAD SCREWS (1S).

å

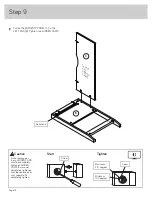

Fasten the CABINET RIGHT (35GA) to the EXTENSION BRACKETS (43G)

on the UPRIGHT (D). Use two GOLD 5/16" FLAT HEAD SCREWS (3S)

through holes #1 and #3.

å

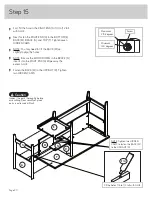

NOTE: Use the exact holes shown in the EXTENSION BRACKETS.

å

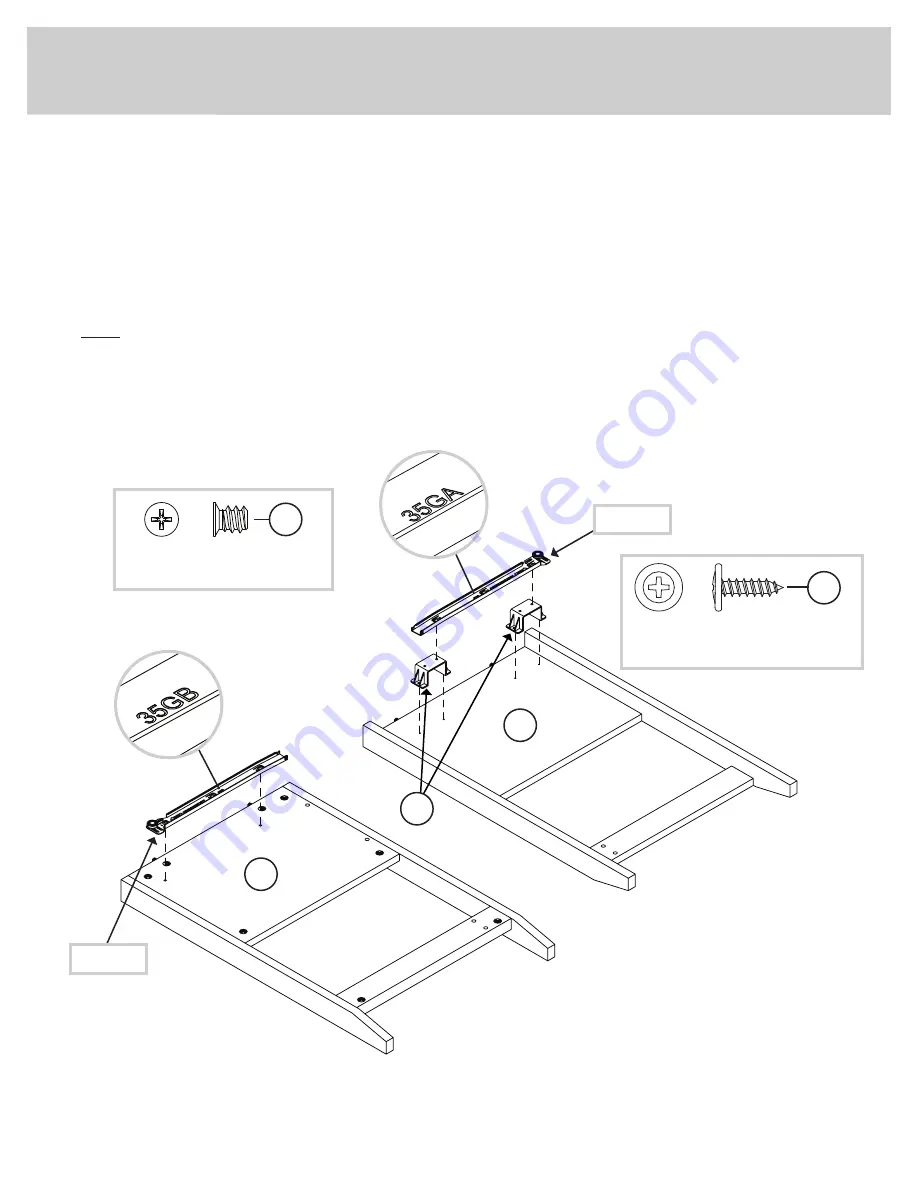

Fasten the CABINET LEFT (35GB) to the LEFT END (B). Use two GOLD

5/16" FLAT HEAD SCREWS (3S) through holes #1 and #3.

Step 8

Page 13

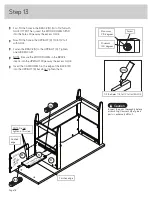

B

D

1

2

3

1

2

3

Roller end

Roller end

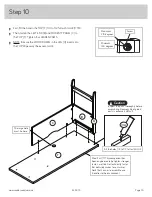

GOLD 5/16" FLAT HEAD SCREW

(4 used for the RAILS)

3S

BLACK 9/16" LARGE HEAD SCREW

(4 used for the BRACKETS)

1S

43G