å

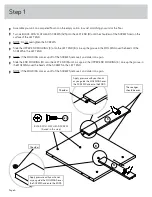

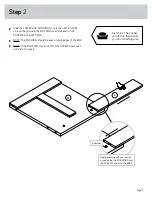

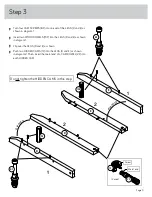

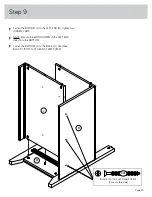

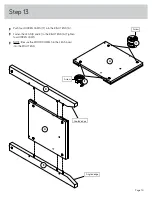

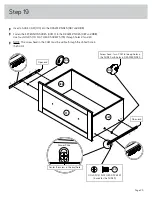

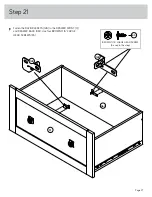

Fasten the BOTTOM (J) to the LEFT END (B). Tighten two

HIDDEN CAMS.

å

NOTE: Be sure the WOOD DOWEL in the LEFT END

insert into the BOTTOM.

å

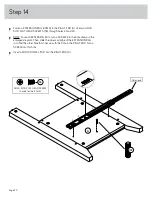

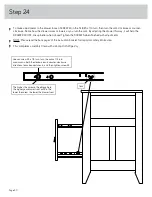

Fasten the BOTTOM (J) to the BACK (O). Use three

BLACK 1-15/16" FLAT HEAD SCREWS (113S).

Step 9

J

B

Page 15

O

BLACK 1-15/16" FLAT HEAD SCREW

(3 used in this step)

113S