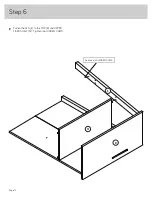

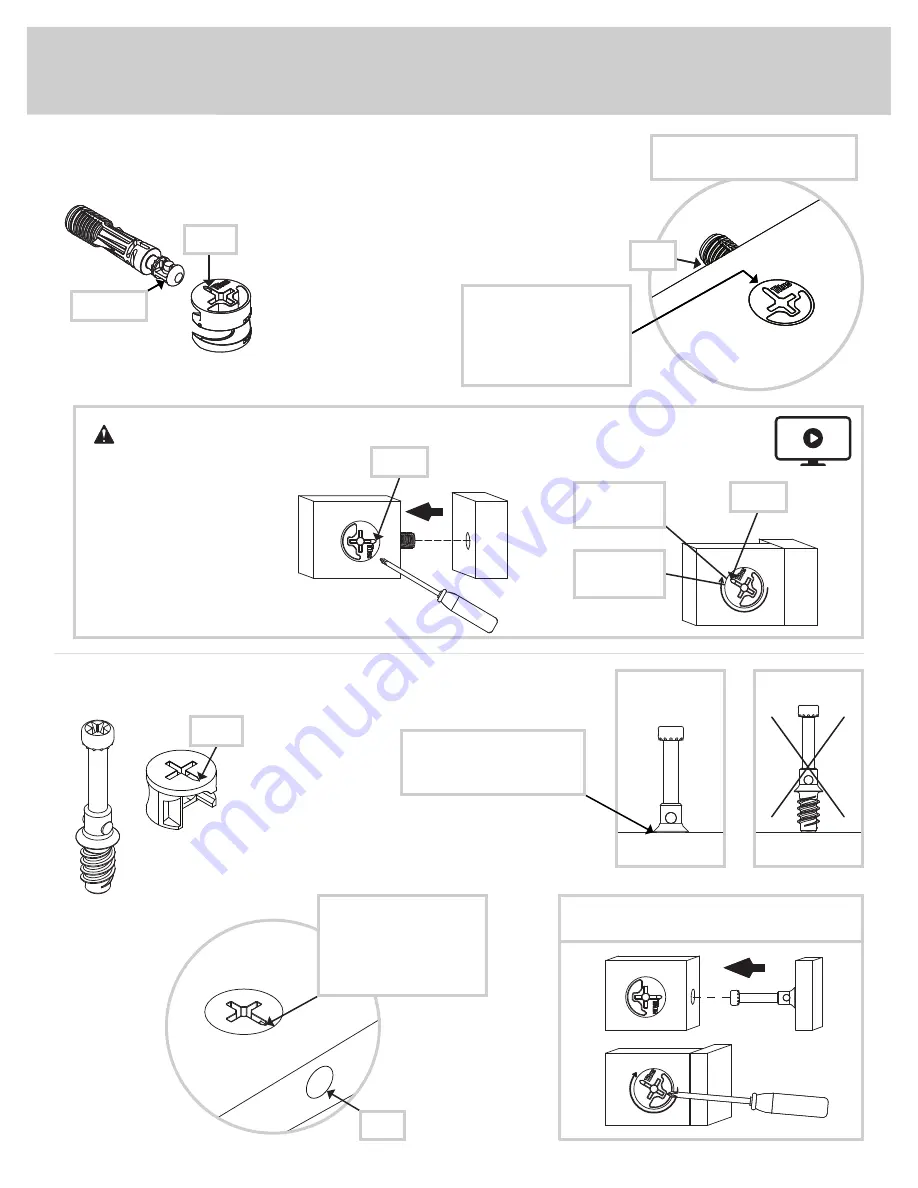

Hardware Usage Guide

Start

Tighten

Arrow

Minimum

190 degrees

Caution

Risk of damage or

injury. HIDDEN CAMS

must be completely

tightened. HIDDEN

CAMS that are not

completely tightened

may loosen, and parts

may separate. To

completely tighten:

Arrow

Maximum

210 degrees

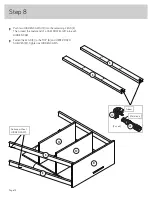

3.

Start

Tighten

Arrow

Minimum

190 degrees

Caution

Risk of damage or

injury. HIDDEN CAMS

must be completely

tightened. HIDDEN

CAMS that are not

completely tightened

may loosen, and parts

may separate. To

completely tighten:

Arrow

Maximum

210 degrees

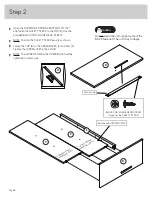

HOW TO USE A HIDDEN CAM & CAM DOWEL

Hole

Hidden Cam

Cam Dowel

2.

Hole

Hidden Cam

Cam Dowel

Insert the metal end of the CAM

DOWEL into the HIDDEN CAM.

Metal end

Arrow

1.

Push a HIDDEN CAM into

the part. The arrow in the

HIDDEN CAM must point

toward the hole in the

edge of the board.

Cam Screw

Hidden Cam

Arrow

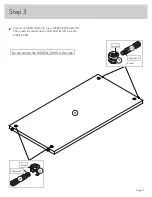

Push a HIDDEN CAM into

the part. The arrow in the

HIDDEN CAM must point

toward the hole in the

edge of the board.

Hole

2.

3.

1

2

Insert the CAM SCREW into the HIDDEN CAM.

Tighten the HIDDEN CAM.

HOW TO USE A HIDDEN CAM & CAM SCREW

Turn the CAM SCREW until

the shoulder is against the

surface of the part.

1.

426135

www.sauder.com/service

Page 6