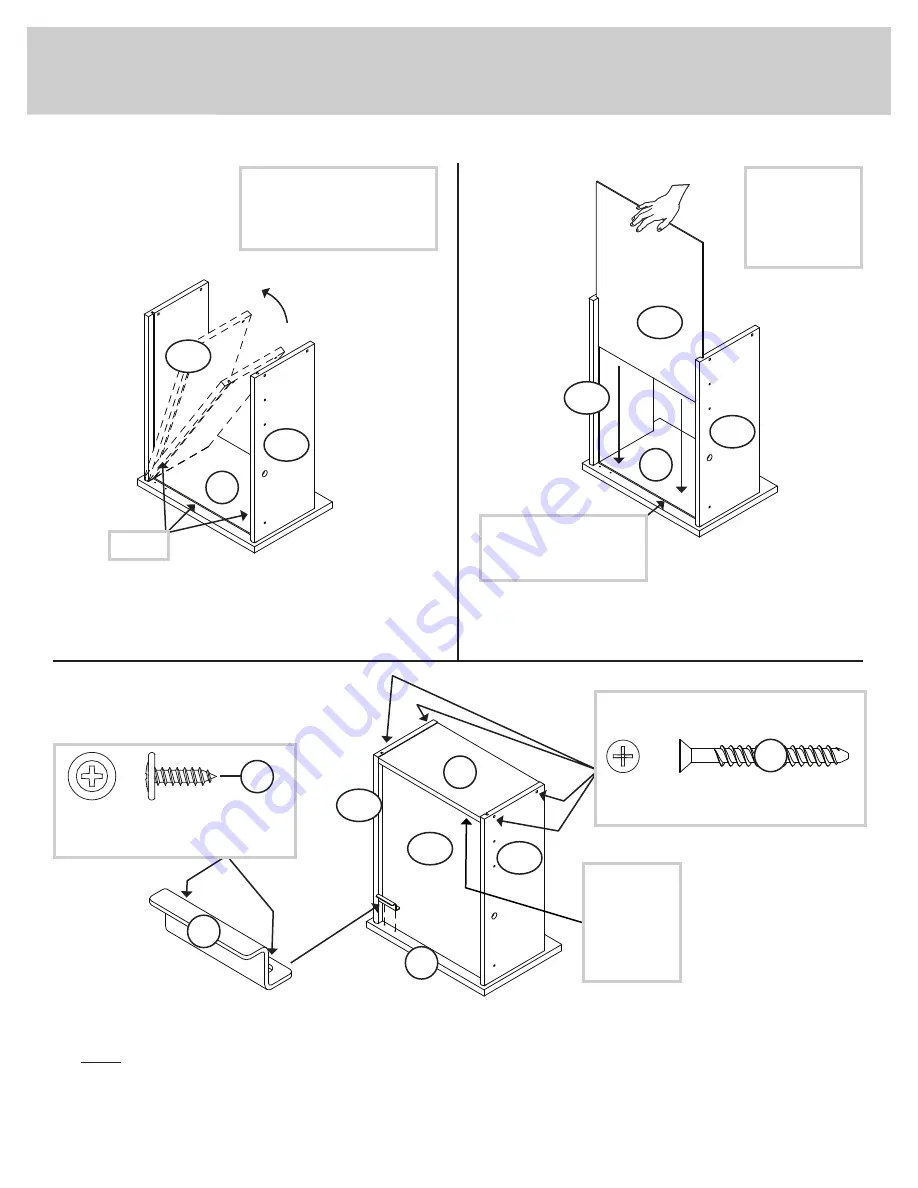

Step 24

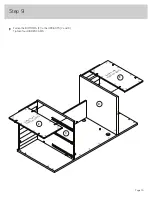

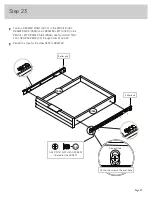

With the palm of

your hand, tap

the DRAWER

BOTTOM down

into the groove.

å

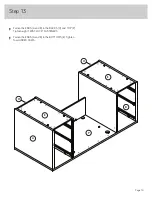

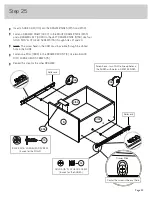

Fasten the DRAWER BACK (D77) to the DRAWER SIDES (D133 and D139). Use four BLACK 1-9/16" FLAT HEAD SCREWS (30S).

å

NOTE: Be sure the DRAWER BOTTOM (D708) inserts into the groove of the DRAWER BACK (D77).

å

Repeat this step for the other drawer.

å

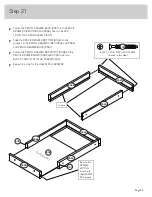

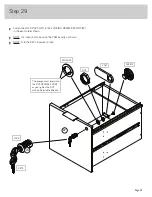

Fasten the Z-LOCK BRACKET (77G) to one of the DRAWER FRONTS (K) exactly as shown. Use two BLACK 9/16" LARGE

HEAD SCREWS (1S).

1

2

3

å

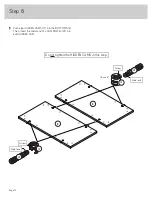

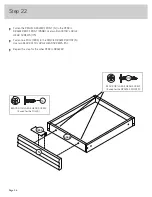

Insert the DRAWER SIDES (D133 and D139) at an angle

into the slot at each end of the DRAWER FRONT (K).

å

Slide the DRAWER BOTTOM (D708) into the

grooves in the DRAWER SIDES (D133 and D139)

and DRAWER FRONT (K).

The tabs should insert freely

into the slots. Gently tilt the

DRAWER SIDES side to side

until the tabs slip into the slots.

Groove

30S

Start each screw a few turns before

completely tightening any of them.

BLACK 1-9/16" FLAT HEAD SCREW

(8 used in this step)

Be sure the DRAWER

BOTTOM inserts into the

DRAWER FRONT groove.

K

D139

D708

D139

D139

D708

D133

D133

D133

K

D77

Unfi

nished

sur

face

Be sure the

DRAWER

BOTTOM

inserts into

the DRAWER

BACK groove.

77G

K

BLACK 9/16" LARGE HEAD SCREW

(2 used for the BRACKET)

1S

Page 28