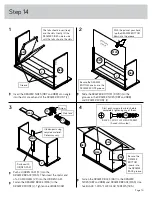

Step 14

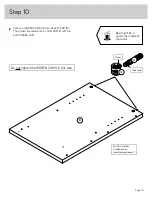

Arrow

1F

2F

Metal end

å

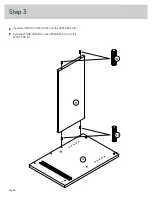

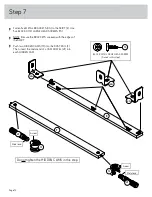

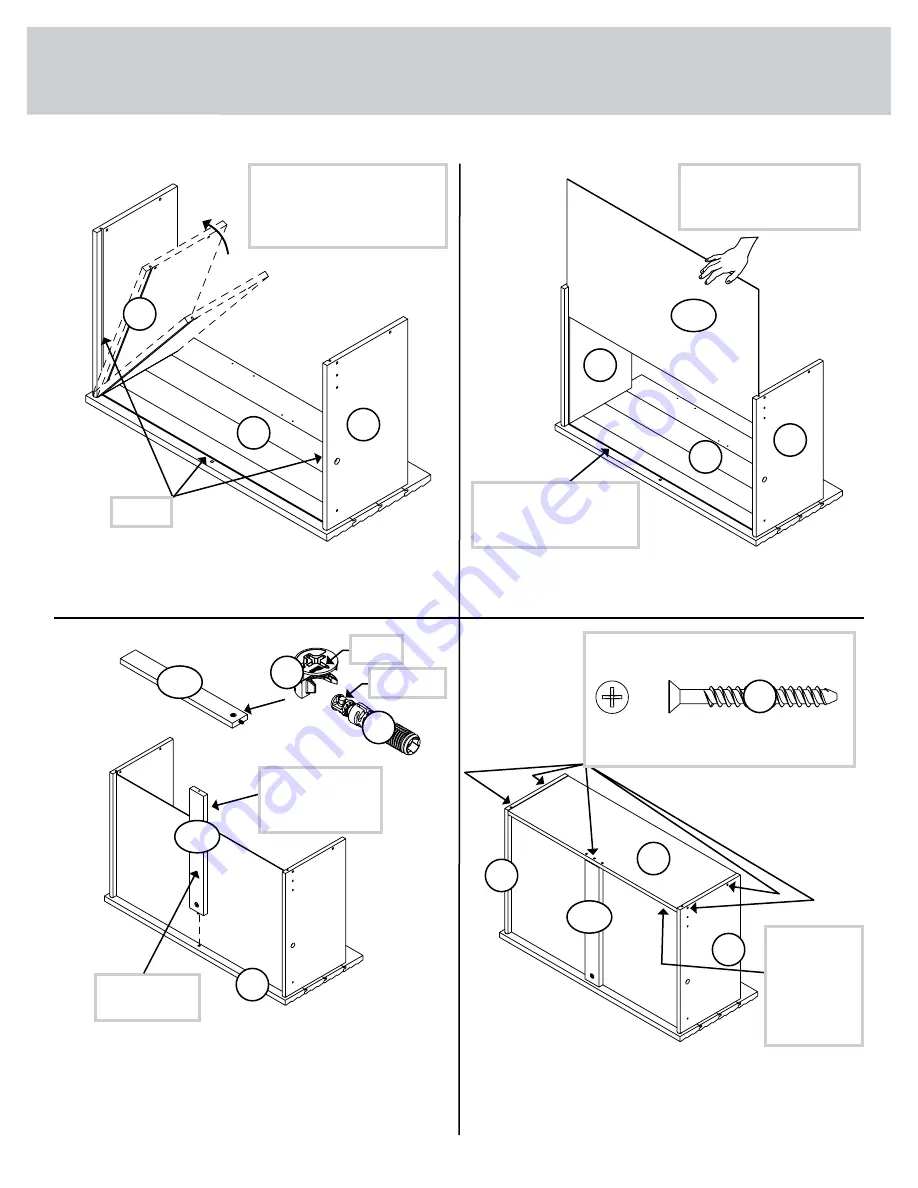

Insert the DRAWER SIDES (D87 and D88) at an angle

into the slot at each end of the DRAWER FRONT (J).

å

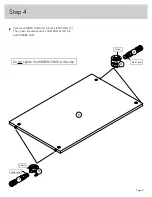

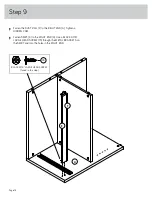

Slide the DRAWER BOTTOM (D729) into the

grooves in the DRAWER SIDES (D87 and D88)

and DRAWER FRONT (J).

å

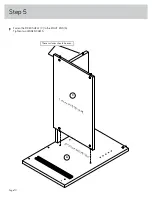

Push a HIDDEN CAM (1F) into the

DRAWER BRACE (M63). Then insert the metal end

of a CAM DOWEL (2F) into the HIDDEN CAM.

å

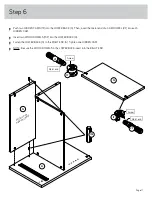

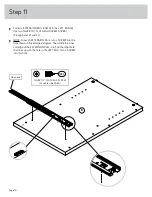

Fasten the DRAWER BRACE (M63) to the

DRAWER FRONT (J). Tighten one HIDDEN CAM.

å

Fasten the DRAWER BACK (D61) to the DRAWER

SIDES (D87 and D88) and DRAWER BRACE (M63). Use

five BLACK 1-9/16" FLAT HEAD SCREWS (30S).

Surface with

HIDDEN CAM

1

2

3

4

Be sure the DRAWER

BOTTOM inserts into the

DRAWER FRONT groove.

Groove

J

J

J

D87

D88

Unfinished

surface

Be sure the

DRAWER

BOTTOM

inserts into

the DRAWER

BACK groove.

30S

Start each screw a few turns before

completely tightening any of them.

BLACK 1-9/16" FLAT HEAD SCREW

(5 used in this step)

The tabs should insert freely

into the slots. Gently tilt the

DRAWER SIDES side to side

until the tabs slip into the slots.

With the palm of your hand,

tap the DRAWER BOTTOM

down into the groove.

M63

M63

Hidden part using

recycled material.

Color may vary.

M63

D87

D88

D87

D88

D729

D61

Page 19