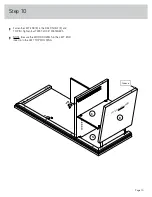

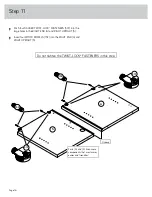

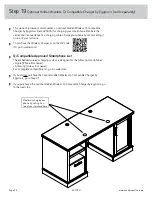

Step 11

A

S

37F

37F

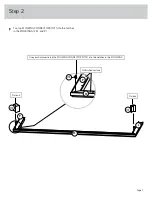

Do not tighten the TWIST-LOCK® FASTENERS in this step.

å

Push four SAUDER TWIST-LOCK® FASTENERS (37F) into the

large holes in the RIGHT END (A) and RIGHT UPRIGHT (S).

å

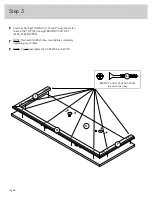

Insert four WOOD DOWELS (15F) into the RIGHT END (A) and

RIGHT UPRIGHT (S).

15F

15F

Groove

Page 16

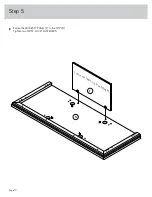

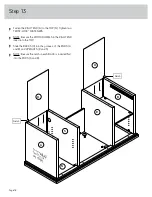

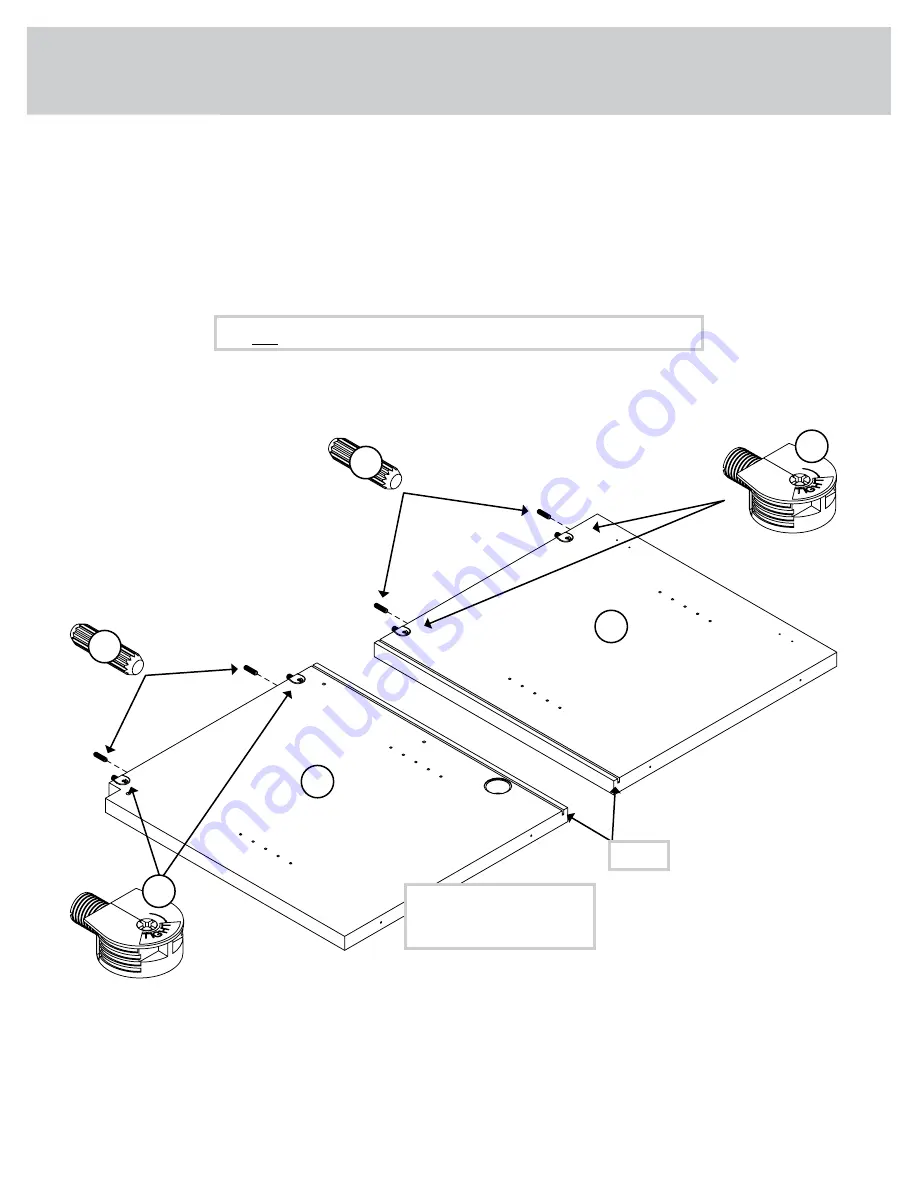

Parts (A) and (S). Even more

components that are sturdier,

easier, and friendlier!