Step 1

å

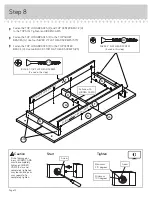

Assemble your unit on a carpeted fl oor or on the empty

carton to avoid scratching your unit or the fl oor.

å

To begin assembly, push a SAUDER TWIST-LOCK®

FASTENER (10F) into the large holes in the TOP

SHORT BRACES (G).

Page 5

(8 used)

10F

Do not tighten the TWIST-LOCK® FASTENERS in this step.

G

G