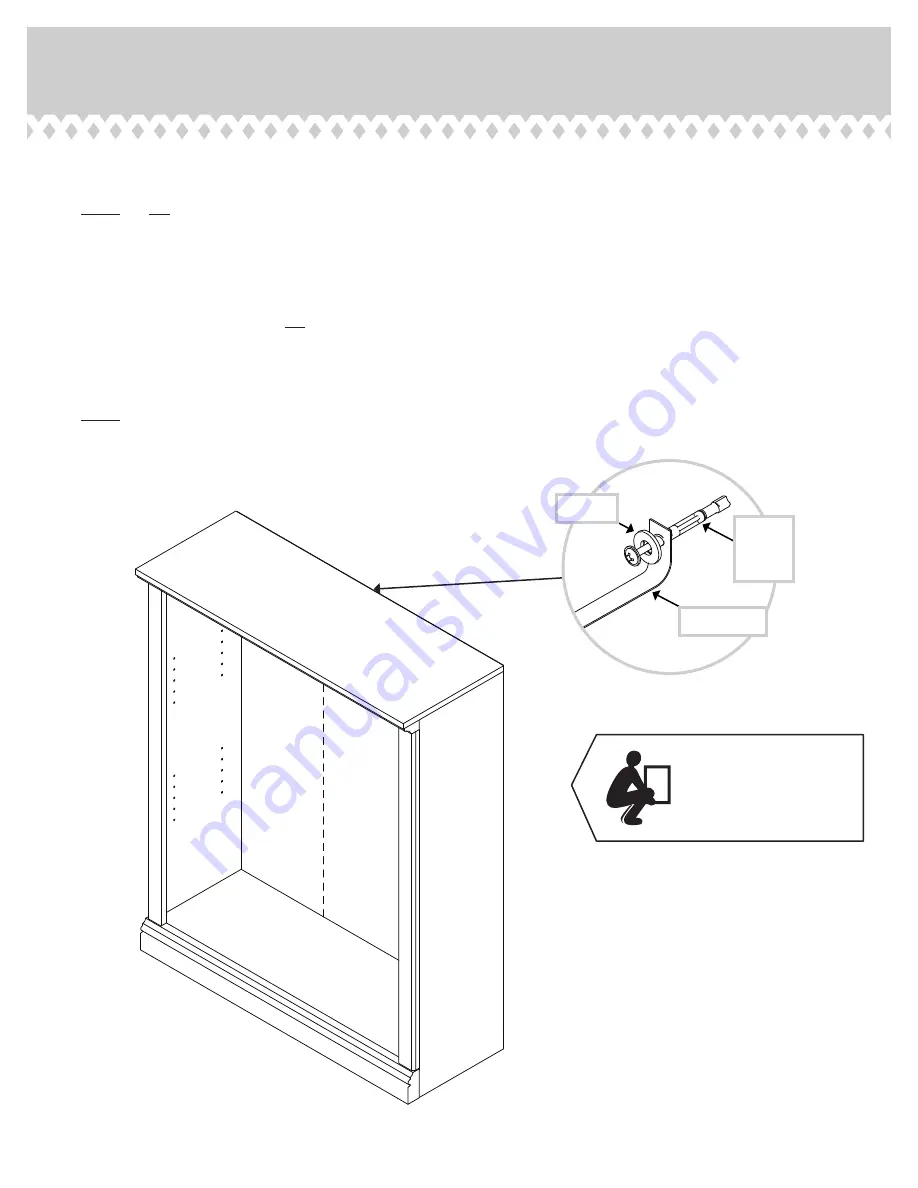

Step 8

å

Carefully stand your unit upright in its fi nal position against a wall.

å

NOTE: Do not turn the SAFETY DRYWALL ANCHOR (61M) into a wall stud. If you prefer to fasten the SAFETY

STRAP to a wall stud, go to your local hardware store for proper hardware.

å

INSTALLATION INSTRUCTIONS:

1. Insert the SAFETY DRYWALL ANCHOR through the WASHER and the end of the SAFETY STRAP.

2. Using a Phillips screwdriver or a hand drill, press the screw slightly onto the drywall just below the top surface of your

unit so the SAFETY STRAP will not be visible.

3. Apply pressure; turn the screw until a pilot hole is made and the nylon sheath slips through.

4. Turn the screw until it is fl ush against the wall and you feel a fi rm resistance.

5. Continue to turn until the screw starts spinning freely.

å

NOTE: Before moving your unit to a diff erent location, unscrew the SAFETY DRYWALL ANCHOR from your wall. The

nylon sheath will remain behind your wall.

Page 12

Pro Tip: Lift with your

legs. And, you know,

your arms.

Safety

drywall

anchor

Safety strap

Washer