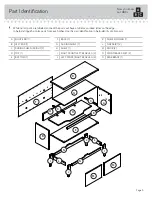

Hardware Identifi cation

å

Screws are shown actual size. You may receive extra hardware with your unit.

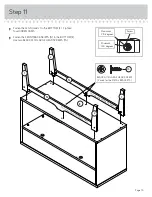

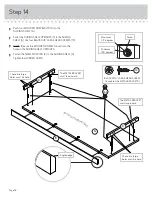

BLACK 9/16" PAN HEAD SCREW - 4

51S

METAL BRACKET - 6

4G

BLACK 9/16" LARGE HEAD SCREW - 16

1S

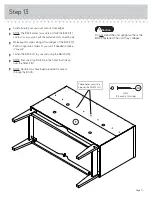

BLACK 7/8" FLAT HEAD SCREW - 10

31S

WASHER - 2

9I

BLACK 1-7/8" FLAT HEAD SCREW - 6

2S

3S

GOLD 5/16" FLAT HEAD SCREW - 8

METAL PIN - 2

1R

MAGNETIC CATCH - 2

12I

CAM SCREW - 4

8F

WOOD DOWEL - 4

15F

NAIL - 44

1N

HIDDEN CAM - 20

1F

CAM DOWEL - 16

2F

CAM COVER - 4

50P

PIVOT HINGE- 4

41H

PIVOT HINGE

BRACKET- 2

54G

STRIKE PLATE

BRACKET- 2

14I

GOLD 2-3/4" FLAT HEAD BOLT - 4

109S

Page 4

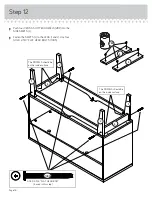

(EXTENSION SET SHOWN SEPARATED)

P

EXTENSION RAIL - 2

Q

EXTENSION SLIDE - 2

CROSS SLOTTED DOWEL - 4

28F