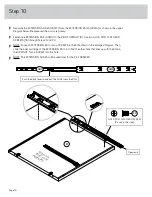

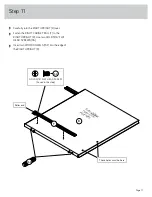

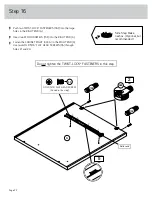

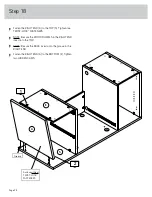

Step 11

å

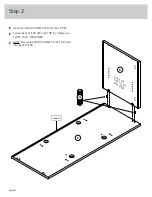

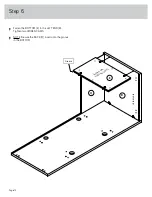

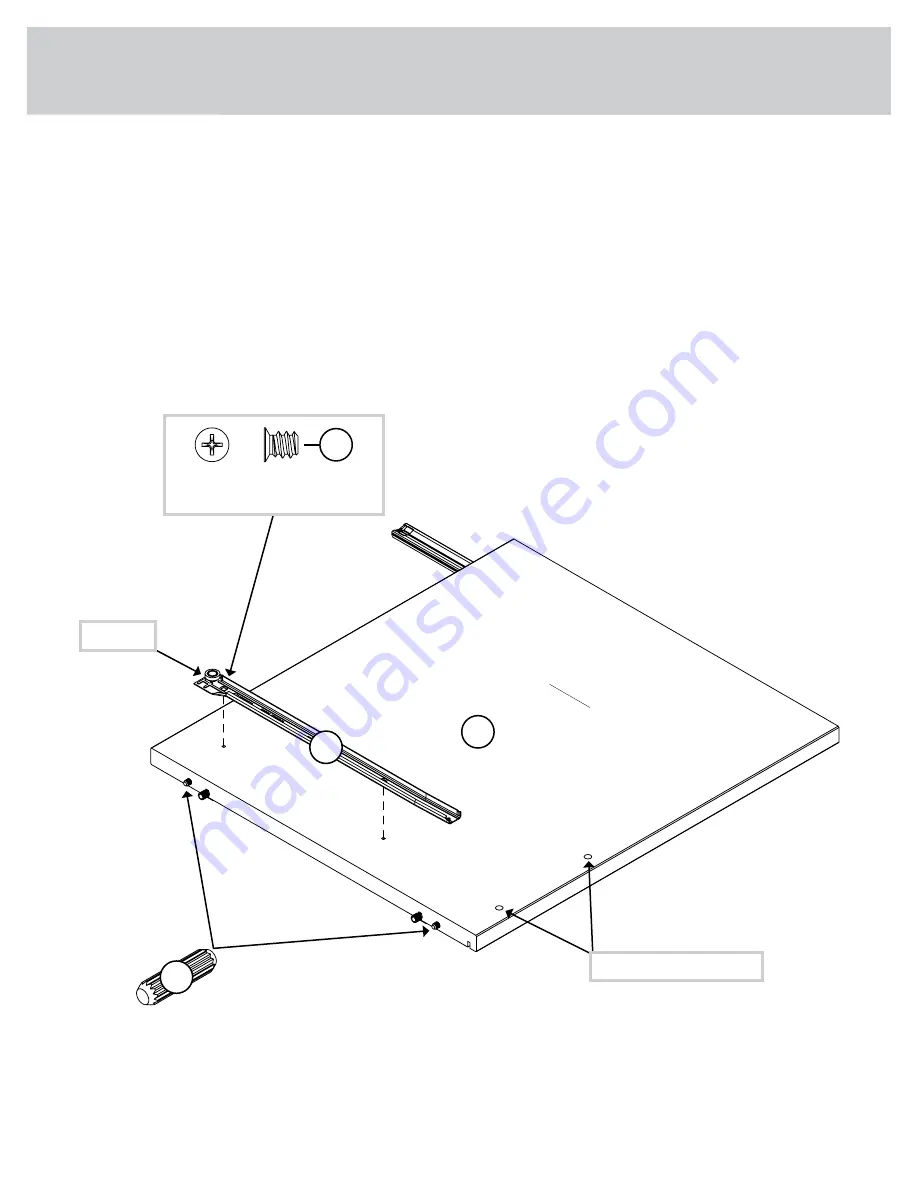

Carefully turn the RIGHT UPRIGHT (D) over.

å

Fasten the RIGHT CABINET RAIL (T) to the

RIGHT UPRIGHT (D). Use two GOLD 5/16" FLAT

HEAD SCREWS (3S).

å

Insert two WOOD DOWELS (15F) into the edge of

the RIGHT UPRIGHT (D).

T

These holes must be here.

15F

D

Page 17

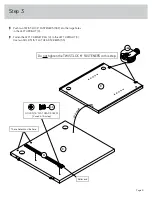

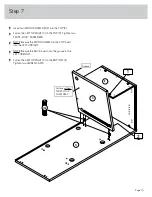

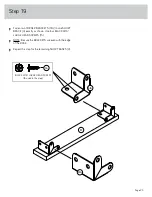

Surface

without

TWIST

-LOCK

®

FASTE

NERS

Roller end

GOLD 5/16" FLAT HEAD SCREW

(2 used in this step)

3S