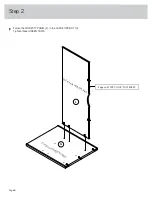

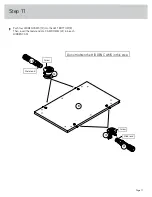

Part Identification

å

While not all parts are labeled, some of the parts will have a label or an inked letter on the edge

to help distinguish similar parts from each other. Use this part identification to help identify similar parts.

Now you know

our ABCs.

A

RIGHT END (1)

B

LEFT END (1)

C

TOP (1)

D

SMALL TOP (1)

D78

LARGE DRAWER BACK (1)

D87

LARGE RIGHT DRAWER SIDE (1)

D88

LARGE LEFT DRAWER SIDE (1)

D109 SMALL DRAWER BACK (2)

D130 SMALL RIGHT DRAWER SIDE (2)

D136 SMALL LEFT DRAWER SIDE (2)

D708 DRAWER BOTTOM (3)

E

RIGHT UPRIGHT (1)

F

LEFT UPRIGHT (1)

G

LARGE UPRIGHT (1)

H

LEFT BASE (2)

J

RIGHT BOTTOM (1)

K

ADJUSTABLE SHELF (1)

L

MODESTY PANEL (1)

M

SMALL MODESTY PANEL (1)

O

RIGHT BASE (2)

P

SIDE BASE (4)

Q

KEYBOARD SHELF (1)

R

LEFT BOTTOM (1)

S

LEFT BACK (1)

T

RIGHT BACK (1)

U

DRAWER FRONT (2)

V

DOOR (1)

W

LOCKING DRAWER FRONT (1)

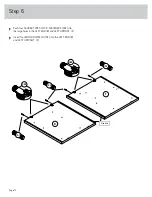

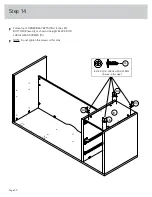

A

B

C

D

E

F

G

H

O

O

J

K

L

M

P

P

P

P

Q

R

S

T

U

V

W

H

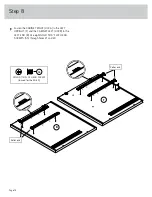

D78

D87

D88

D708

D708

D130

D136

D109

Page 3