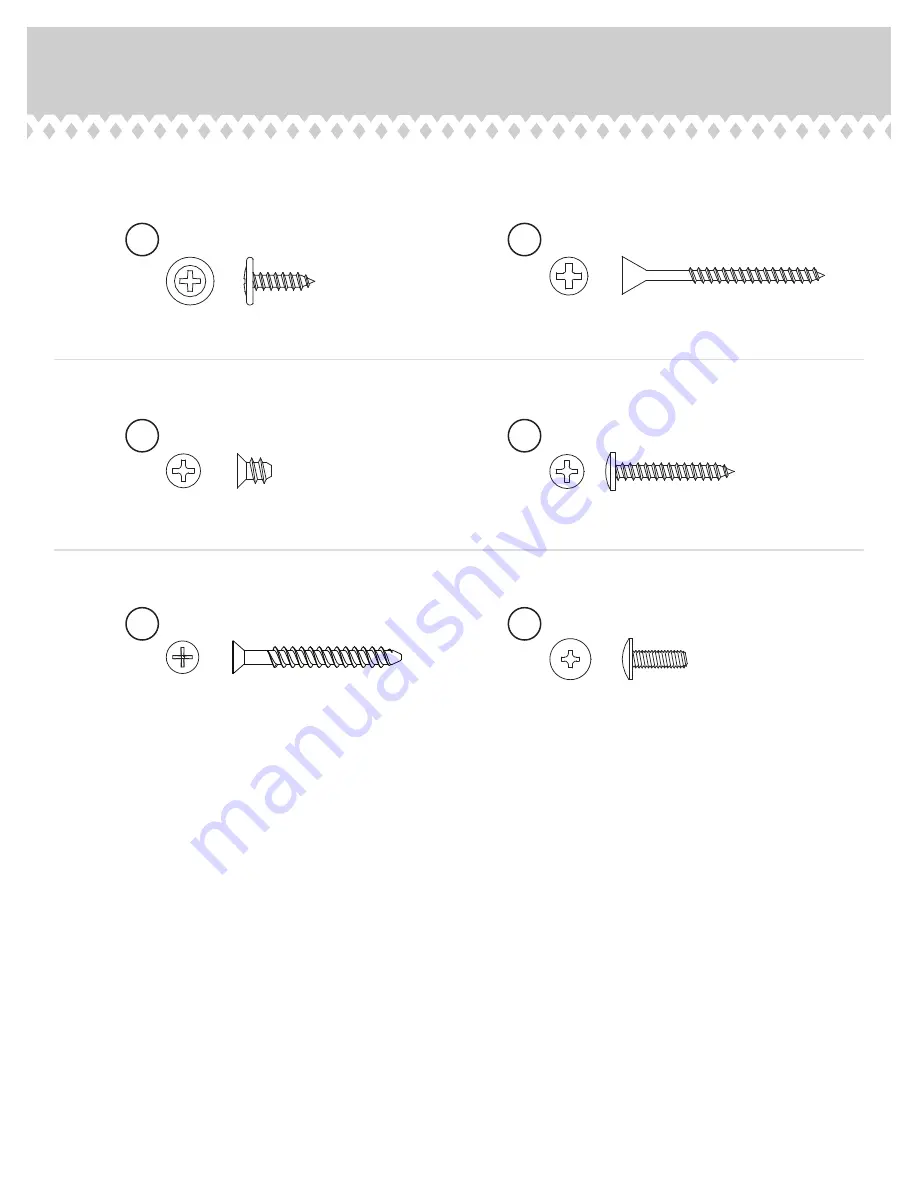

Hardware Identifi cation

å

Screws are shown actual size. You may receive extra hardware with your unit.

Page 5

BLACK 1-1/8" PAN HEAD SCREW - 16

9S

SILVER 1/2" MACHINE SCREW - 8

38S

BLACK 9/16" LARGE HEAD SCREW - 24

1S

BLACK 1-7/8" FLAT HEAD SCREW - 12

2S

3S

GOLD 5/16" FLAT HEAD SCREW - 32

30S

BLACK 1-9/16" FLAT HEAD SCREW - 16