å

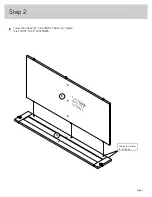

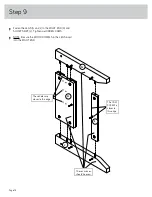

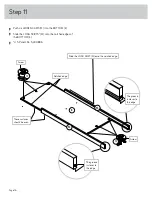

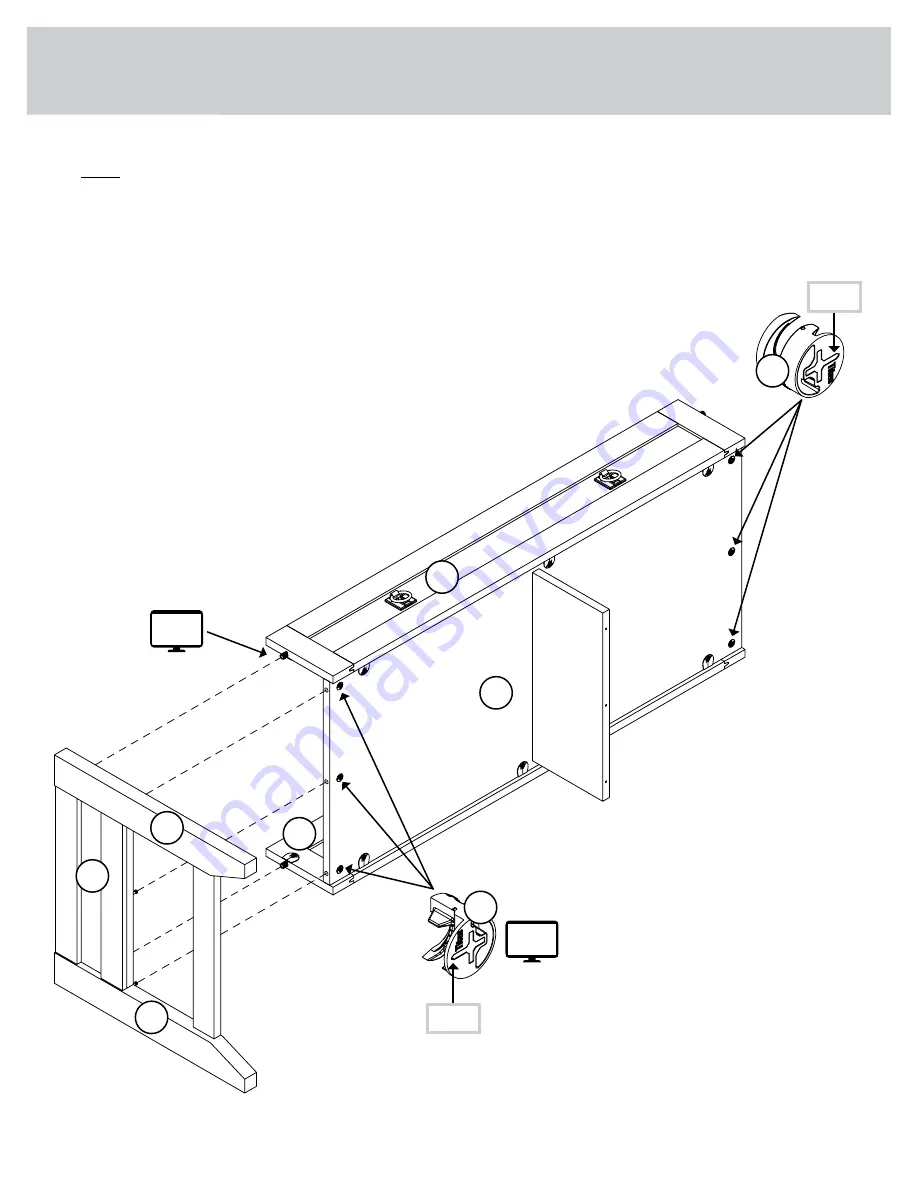

NOTE: This step shows a different view of the assembled parts.

å

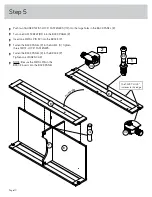

Push six HIDDEN CAMS (1F) into the SHELF (D).

å

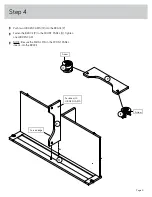

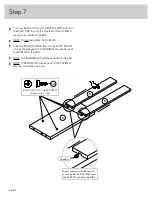

Fasten the LEGS (G and J) to the PANELS (Q and R). Tighten two

TWIST-LOCK® FASTENERS.

å

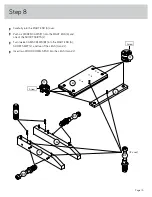

Fasten the RIGHT END (A) and LEGS (G and J) to the SHELF (D).

Tighten three HIDDEN CAMS.

Step 10

Page 15

A

G

J

D

R

Q

Arrow

1F

Arrow

1F

1

2