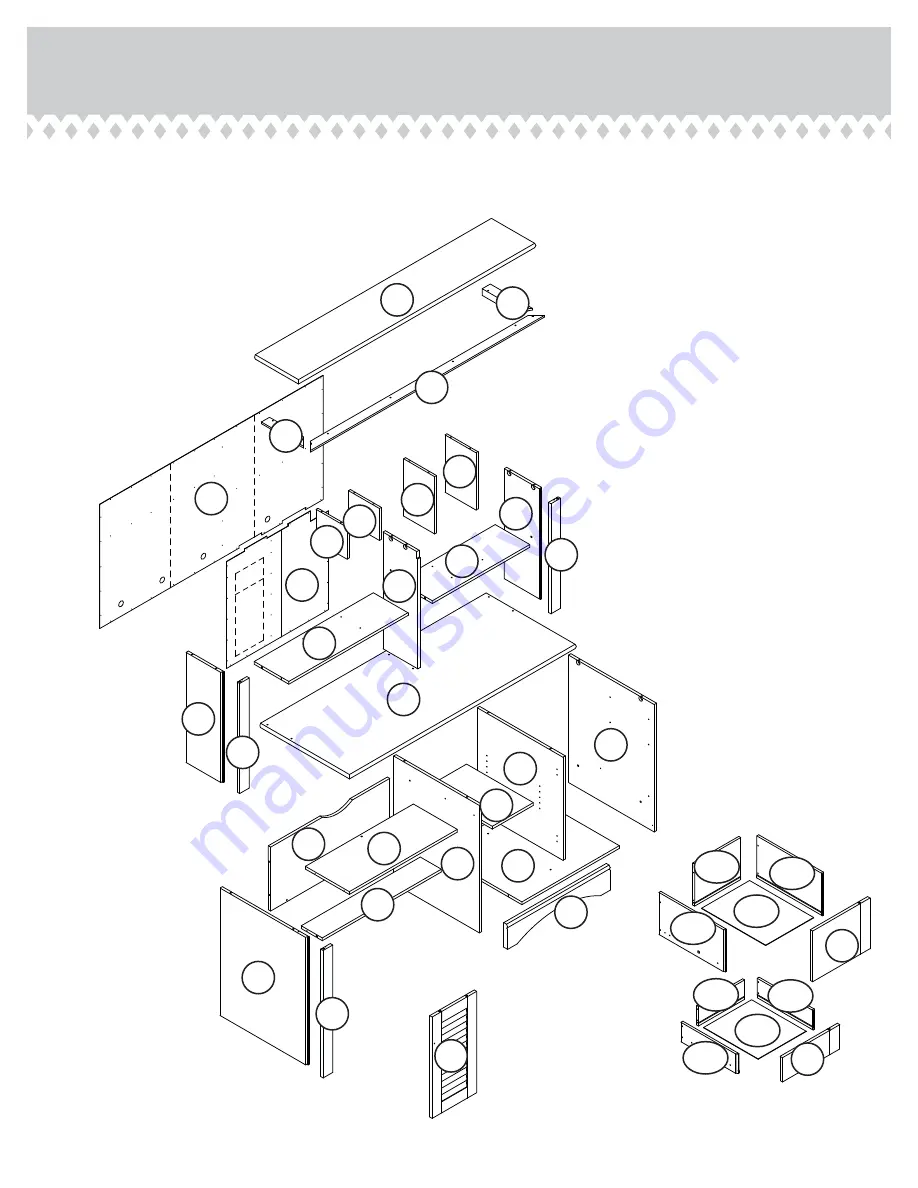

Part Identifi cation

å

While not all parts are labeled, some of the parts will have a label or an inked letter on the edge

to help distinguish similar parts from each other. Use this part identifi cation to help identify similar parts.

A

B

C

D

E

F

G

H2

I

J

K

L

M

N

O

P

Q

R

S

S

T

T

U

V

W

X

Y

Z

AA

BB

CC

D24

D25

D88

D78

D87

D716

D708

D109

Page 3

Y