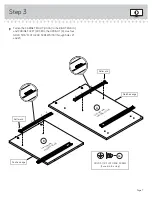

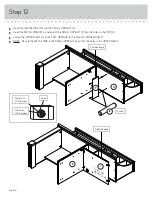

Step 3

Page 7

A

D

Sur

face with

HIDDEN CAMS

Sur

face with

HIDDEN CAMS

å

Fasten the CABINET RIGHT (40CA) to the RIGHT END (A)

and CABINET LEFT (40CB) to the UPRIGHT (D). Use four

GOLD 5/16" FLAT HEAD SCREWS (3S) through holes #1

and #3.

GOLD 5/16" FLAT HEAD SCREW

(4 used in this step)

3S

1

2

3

4

1

2

3

4

Roller end

Roller end

Finished edge

Notched edge