å

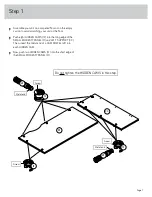

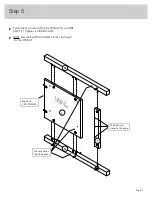

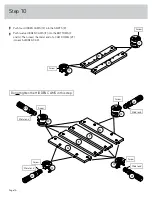

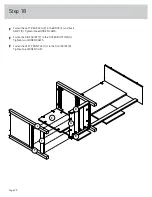

Push two HIDDEN CAMS (1F) into the short edge of

the UPRIGHT (J). Then, insert the metal end of a CAM

DOWEL (2F) into each HIDDEN CAM.

å

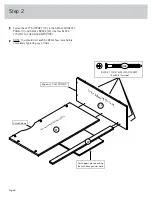

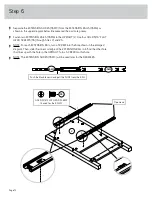

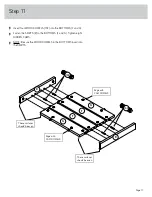

Now, push six HIDDEN CAMS (1F) into the UPRIGHT (J)

and one SIDE SKIRT (T).

Step 3

Page 9

Arrow

1F

2F

Metal end

1F

Arrow

1F

Arrow

J

T

Do not tighten the HIDDEN CAMS in this step.

The holes are

closer to this edge.