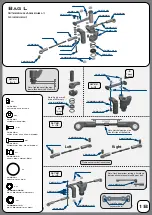

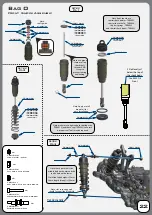

Shock Filling Instructions

For both front and rear shocks

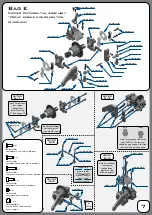

21

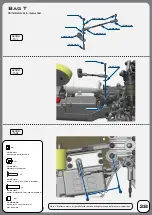

Step 1.

Extend the shock shaft all the way down. Fill the shock with oil until the body is

approximately 90% full.

Step 2.

Slowly pump the shock shaft up and down about 3-5 times to release air bubbles from

underneath the piston.

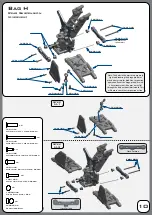

Step 3.

Let the shock rest vertically with the shock shaft fully extended for five minutes or until all

of the air bubbles have released.

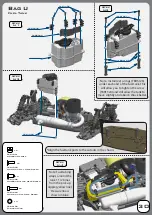

Step 4.

Push the shaft in so that ~20mm of shaft is between the bottom of the cartridge and the

top of the rod end. Make sure that you match the rebound amount between the left and right

shocks. The vented cap design doesn’t provide much rebound. We've found that running the

least amount of (0%) rebound in both the front and rear shocks gives the most consistent

overall performance.

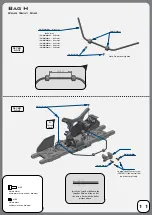

Step 5.

Next you will top off the shock with oil. Fill to just a hair below full, level with the top of

the shock body, but not doming over the top. If you do overfill the shock, it won’t hurt

performance, it will just spill out.

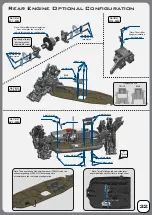

Step 6.

In this step you will be placing the bladder inside the shock cap. Slowly screw the shock

cap onto the shock body while holding the shock vertically. Continue screwing slowly until oil

begins to bleed out of the bleeder hole. At this point, rotate the shock over about 50-60 degrees

with the bleeder hole pointing up. Continue to screw the cap on and bleed the shock until the

cap is tight. Wipe off excess oil. A good hand tightening is all that is needed, but feel free to

use tools to make them tighter if you wish.

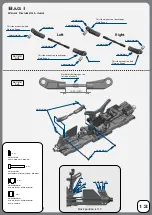

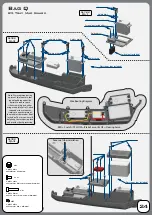

The following steps and information will provide you with the proper way to fill and bleed

your Tekno RC NB48 shocks.

After thorough testing, we've found it's easiest to complete steps 1 through 3 on

each shock before moving onto step 4. By the time you've finished step 3

on the last shock the first one should be ready for step 4.

Note:

It’s very important to consider ambient temperature when selecting shock oil viscosity.

We recommend #500 cst for the front suspension and #400 cst for the rear suspension for 70-80°F

(21-26°C) outside temperature. You may need to go up or down 50-100cst in shock oil for each

10°F (5°C) of temperature change (lower temperature -> lower viscosity). The oils in the kits are

a great starting point. We suggest starting with the kit oils and moving up or down depending

on the track conditions and ambient temperature.You can build the shocks in any manner you

prefer, but we’ve found this way provides the best handling and more consistent shocks.

They will also last longer between rebuilds.

Use part #’s TKR6008 (shock bushings and cartridge guides) and TKR6009

(o-ring pack) to rebuild your shocks regularly.

We also offer a line of optional CNC shock pistons (TKR6050 -> TKR6054).

The included pistons are TKR6051 (8x1.3mm holes).