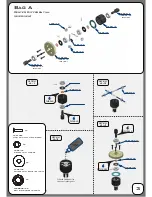

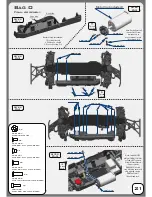

Shock Filling Instructions

For both front and rear shocks

17

The following steps and information will provide you with the proper way to fill and bleed your shocks.

After thorough testing, we've found it's easiest to complete steps 1 through 3 on each shock before moving

onto step 4. By the time you've finished step 3 on the last shock the first one will be ready for step 4.

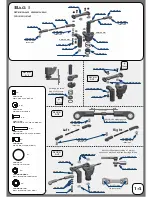

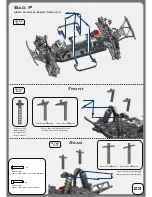

Standard or Vented Cap Build:

Step 1. Extend the shock shaft all the way down. Fill the shock with oil until the body is approximately 90% full.

Step 2. Slowly pump the shock shaft up and down 3-5 times to release air bubble from underneath the piston.

Step 3. Let the shock rest vertically with the shock shaft fully extended for five minutes or until all the air bubbles

have released.

Step 4. Push the shaft in for the amount of rebound desired. For example, to achieve 0% rebound push the shaft

in all the way (in this case, about ¼” of shaft showing). For 50% rebound, push the shaft in half way. Make sure

that you match the rebound amount between the left and right shocks. We've found that running 0% rebound

in both front and rear shocks gives great overall performance.

Step 5. Next you will top off the shock with oil. The goal is not to fill the body to the brim but only to fill it enough

so that when the bladder is placed on top there will be no air underneath. If you do overfill the shock, it won’t hurt

performance, it will just spill out and make a little bit of a mess.

Step 6. In this step you will be placing the bladder on top of the shock body. While holding the shock shaft in the

desired position from step 4, push the bladder down onto the shock body using your fingertip to fully seat the lip

of the bladder onto the rim of the shock body. If done correctly a small amount of oil should bleed out. If no oil is

released you may have some air trapped underneath the bladder and you will need to remove the bladder and

repeat step 5. Once the bladder is seated onto the shock body, pull the shock shaft down about 20mm. This will

“suck” the bladder down and hold it in place. Carefully wipe away the excess oil that was bled, being careful not

to disrupt the seal of the bladder on the shock body.

Step 7. While continuing to hold the shock vertically, screw the shock cap down onto the body and tighten fully.

The cap will bottom out easily, but the bladder will be sealed tight. You can use an adjustable wrench to hold the

bottom of the shock while tightening the shock cap down to be sure they are tight.

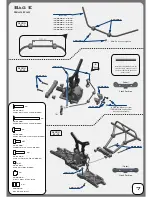

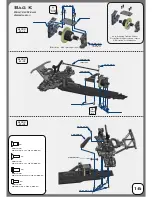

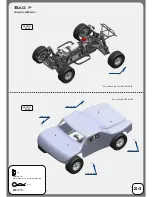

Emulsion Build:

Prep your shock caps TKR6018 (optional for EB48) accordingly by drilling out the large angled bleeder hole in the

top of the cap. Place the larger thin o-rings around the base of the threads where the shock cap screws on

(see diagram). This will seal the cap and the shock body.

Follow steps 1-3 above.

Step 4. Rebound is more of a natural side effect of an emulsion shock. It’s not something that can be set accurately

because you run the risk of hydrolocking the shock if you do not push the shaft all the way in when you bleed it.

For now leave the shaft fully extended.

Step 5. Fill the shock all the way to the top, going over just slightly without spilling to create a small dome.

Step 6. Place a little bit of oil in the shock cap and quickly put the shock cap on the shock body. Tighten the cap all

the way down. Very slowly push the shaft in. Oil will start to bleed out of the top of the cap. While wiping away

excess oil, continue to slowly push the shaft in ALL THE WAY. If no oil comes out when the shaft is fully inserted,

you will need to add more oil and repeat the step. Use the supplied M4x6mm flat head screw and TKR5125 o-ring

to seal the cap.

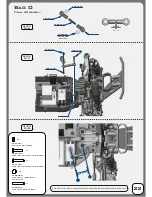

Use part #’s TKR6008 (pistons and guides) and TKR6009 (o-ring pack) to rebuild your shocks regularly.