3

Table 6

- Notifications for leds ZONE1-ZONE4 and Control Panel

Notification

LED ZONE1-ZONE4

CONTROL

PANEL

Fire

Red

+

Attention

x1 red flash every sec.

+

Alarm

x1 red flash every 2 sec.

+

Zone Open

circuit

x1 yellow flash every 2 sec.

+

AL Short cir-

cuit

x2 yellow flashes every 2 sec.

+

Norm

Off

+

«+» - notification is transmitted to CONTROL PANEL,

«-» - notification is not transmitted to CONTROL PANEL

Table 7

- Notifications on the

INTERFACE LED

and CONTROL PANEL

Notification

LED INTERFACE

CONTROL

PANEL

BPA not registered

Off

-

SLC Norm

x1 green flash with a period of

8 sec.

+

Power failure (SLC)

x3 yellow flashes with a period

of 25 sec.

+

SLC loss of connection

Off

-

Registration (via Laser

Pointer) *

x1 red LED for 2 sec.

-

Test

(via

Laser

Pointer) *

x1 red LED for 5 sec.

+

Firmware update*

x1 yellow flash every sec.

-

«

*

» - service indication used during commissioning and service of

BPA,

«-» - notification is not transmitted to CONTROL PANEL,

«+» - notification is transmitted to CONTROL PANEL

7 PREPARING FOR OPERATION

7.1

BPA after transportation under conditions other than operating

conditions, keep unpacked in operating conditions for at least 4 hours.

7.2

BPA must be previously reset or with a correctly remote address

(see 7.4).

Otherwise, rewriting the address is possible only with the la-

ser pointer Astra-942.

7.3 BPA registration

1)

Check the correspondence between the RPA and CONTROL

PANEL firmware version (v5_5 and higher), if necessary, change the

firmware according to the method of p. 8.

2)

Connect RPA to CONTROL PANEL via RS-485 interface.

3)

Add RPA to the CONTROL PANEL according to User Guide.

4)

Connect BPA to the power supply 12 (24) V.

5)

Connect BPA to the power line (terminals "+", "-") and the interface

line (terminals A and B) of the RPA, connect with the power off.

6)

Turn on the external power supply (12 or 24 V) of the BPA, RPA

and CONTROL PANEL (if it was turned off).

7)

Start CONTROL PANEL the mode of Registering devices in the

RPA with a command through the PKM menu, or the CONTROL

PANEL interface "Astra-812 Pro" in accordance with the User guide.

The mode starts for 60 seconds to register a device.

8)

Start the registration mode on the BPA by lighting the BPA IN-

TERFACE led from the button of the Astra-942 laser tester for at least

1 sec.

Attention!

Simultaneous launch of the registration procedure on several ad-

dressable devices is prohibited.

9)

Check in the PKM Configuration Module how the registration

passed:

in case of successful registration, the abbreviated name "BPA" or the

message: "BPAxxx registered" will appear on the screen;

in case of unsuccessful registration, it is necessary to repeat the reg-

istration procedure (p. 7-9).

10)

The procedure is accompanied with messages: "In progress",

"Completed" or "Not completed".

11)

Once registered, the BPA LEDS will display the current power and

load status as shown in Tables 2-7.

Notice

– BPA registration in RPA is possible by turning on the power

supply (from the SLC power line) during initial registration or after cor-

rect removal of the BPA from the RPA, where the BPA was previously

registered, for which:

- connect and register RPA in CONTROL PANEL,

- connect Data line SLC BPA to RPA by connecting terminals A, B of

the same name (do not connect SLC power line from RPA to BPA),

- perform action 7),

- turn on the power supply of the BPA by connecting the terminals of the

same name "+", "-" of the BPA and RPA,

- perform action 9).

If the registration procedure is unsuccessful, it is necessary to repeat

the registration procedure using Astra-942 LP.

Attention!

Do not turn off the power to the CONTROL PANEL, RPA and BPA until

the registration and configuration of all devices in the system are

completed!

At the end of the registration, if it is necessary to store the BPA for a

long time before using it at the facility, it is allowed to turn off its power.

When the power is turned on, re-registration in the same CONTROL

PANEL is not required if BPA has not been forcibly removed from the

CONTROL PANEL according to p. 7.4.

7.4 Removing the BPA

Removing BPA from the CONTROL PANEL memory is performed us-

ing the Configuration Module of the PKM Astra Pro or from the CON-

TROL PANEL Astra-812 Pro menu.

8 FIRMWARE UPDATE

Firmware update is performed on the installed system with con-

nected and registered BPA.

Action order:

1)

connect CONTROL PANEL to PC via USB;

2)

run the FW update module from the PKM Astra Pro;

3)

select the firmware file with the required version and start firmware

update procedure;

4)

after completing the firmware update procedure, close the FW up-

date module on the PC

.

9 INSTALLATION

9.1

During installation it is allowed to use mounting devices (cabinets,

boxes, etc.)

9.2

Wires or power and SLC BPA wires must be located

at least 0.6

m

from high-power and high-frequency cables.

9.3 Installation order

Methods of installation:

a)

directly on the wall (steps

1, 2, 4-6

),

b)

on a din rail (steps

1,

3 - 6

).

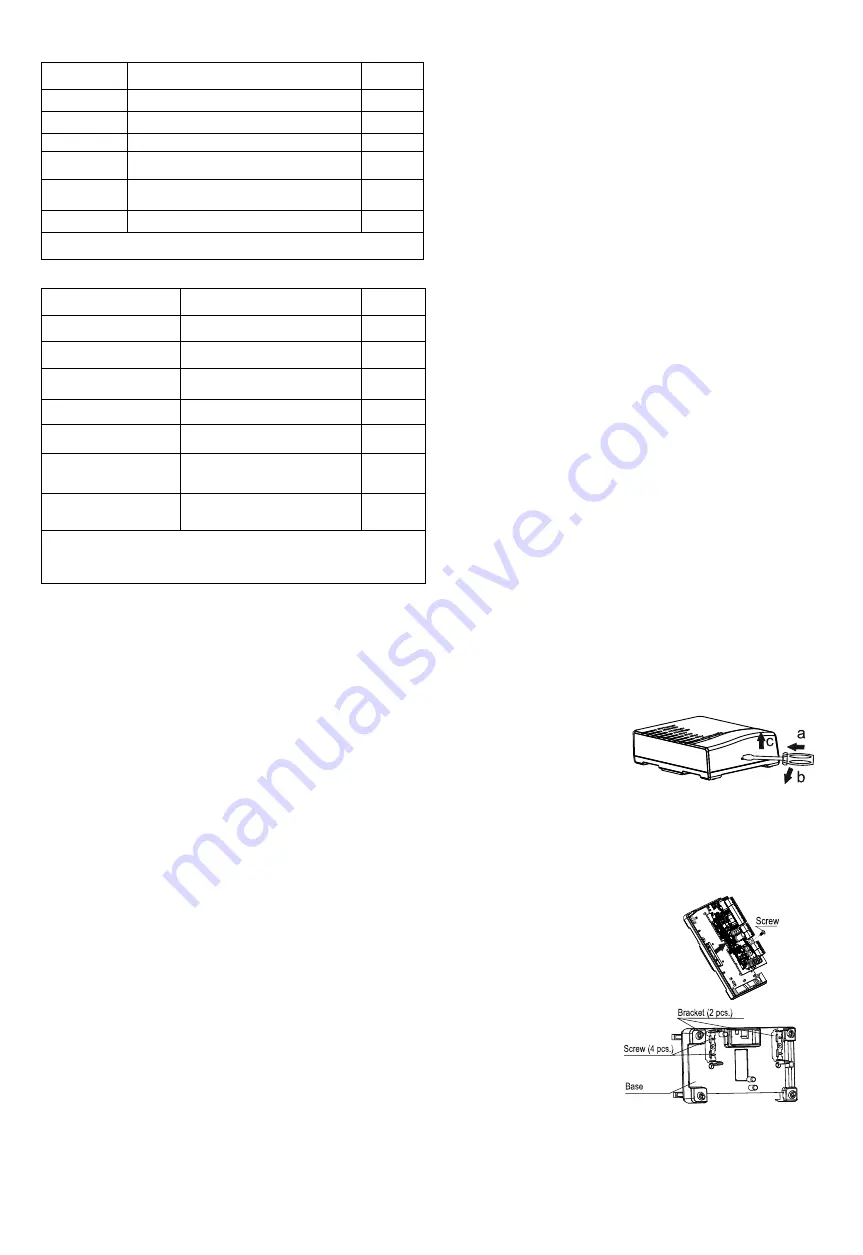

1

Push the base latch out of the cover groove.

Remove the cover

2

Wall Mounting

:

1)

make markings at the attachment point, using the BPA base as

a stencil.

2)

pass the wires of the power supply and the address line of communi-

cation through the holes for the input of wires in the base of the BPA.

3)

fix the base in the place chosen for this.

4)

go to step 4

3 DIN rail installation

:

1)

remove the PCB by unscrewing the

screw securing the PCB to the base

2)

fasten two brackets

from the delivery set with

screws on the outside of

the base

3)

install the PCB