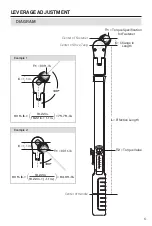

FORMULA INPUTS

The amount of leverage that's applied to a fastener is affected by the position of a

drive tool in relation to the torque wrench's drive tang. When using an off-axis tool that

doesn’t align with the drive tang, such as a crowfoot wrench, you may need to adjust

your torque setting.

T1

— Torque specification for the fastener

L

— Effective length of the torque wrench

TRQ62103: L = 15.62 in.

TRQ62203: L = 19.22 in.

C

— Change in length caused by a crowfoot wrench or other drive tool that

doesn’t align with the drive tang

T2

— Torque value you should use

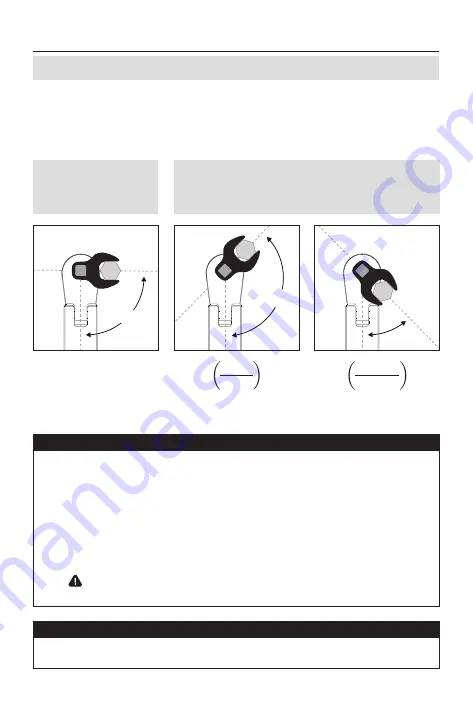

LEVERAGE ADJUSTMENT

T1 ×

= T2

L

L + C

T1 ×

= T2

L

L + (-C)

90º

>90º

<90º

5

If possible, align the

drive tool at a 90-degree

angle to the drive tang.

If a different angle is required, use one of the formulas

below to determine the appropriate torque value.

No formula is needed. Set

the torque value to the

fastener’s specification.

FORMULA OUTPUTS

Measure from the center of the fastener to the center of the drive tang in

a line parallel to the body of the wrench.

See Example 1

See Example 2

CALCULATION