Section 5: Grading and binning resistors

Model DMM7510 7½ Digit Multimeter Application Manual

5-2

DMM7510-904-01 Rev. D March 2021

Instrument connections

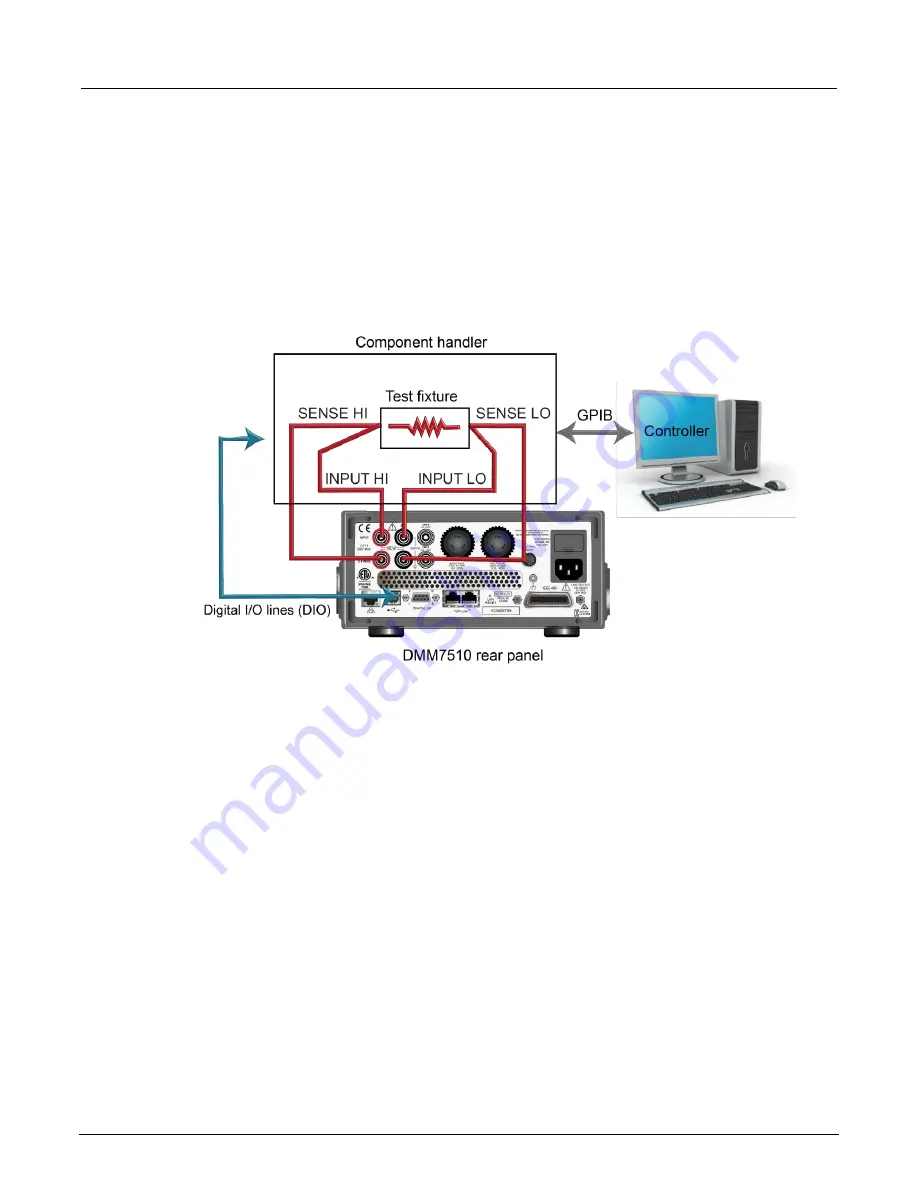

In this example, the output signals that represent the grading results are sent from the DMM7510.

The signals are sent to the component handler, which bins the devices.

The figure below shows the rear-panel connections from the DMM7510 to the test fixture and the

digital lines to the component handler. In addition, there is GPIB communication between the

controller and the component handler.

Figure 9: Device connections for component binning

Resistor grading and binning test

This resistance grading application uses limit tests to inspect a single resistor under test against

multiple limits until the first failure occurs. When the resistor fails, it is placed into a designated

resistance tolerance bin as defined by the limits.

Resistors are placed into bins based on the bit patterns that are assigned to the limits. In this example,

the DMM7510 GradeBinning trigger-model template is used to simplify the application. This

trigger-model template grades components into four tolerance levels (for example, 20%, 10%, 5%,

and 1%) as defined by limits 1 to 4. A single spot measurement is inspected against multiple limits,

which tighten progressively around the same nominal value. When the appropriate tolerance level for

a resistor under test is determined, limit checking stops and the application immediately bins the

tested resistors.

Limits are inspected in ascending numeric order. The measured resistance is checked first against

limit 1, which is the 20% limit. If the resistor fails this limit inspection, its resistance value is outside of

the 20% tolerance band and the trigger model outputs the limit 1 fail pattern, which causes the

component handler to place the resistor in the limit 1 fail bin (20% fail bin).