Summary of Contents for Energy 4010G

Page 1: ...Energy 4010 G Rev 004 1 GB v 004 March 2018 ...

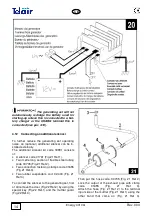

Page 25: ...Rev 004 Energy 4010 G 25 GB WIRING DIAGRAM ENERGY 4010 G ...

Page 27: ...Rev 004 Energy 4010 G 27 GB DRAWING FOR SPARE PARTS LIST ENERGY 4010 G ...

Page 28: ...Energy 4010 G Rev 004 28 GB ...

Page 29: ...Rev 004 Energy 4010 G 29 GB ...

Page 30: ...Energy 4010 G Rev 004 30 GB ...

Page 39: ...Rev 004 Energy 4010 G 39 GB Notes ...

Page 40: ...Energy 4010 G Rev 004 40 GB ...