TIG 3000 G

Vers. 001

12

GB

the pipe (fig. 13 ref. 4), and tighten the clamp. Fix

the silencer using the threaded couplings (fig. 13

ref. 6) and secure the flex hose, making sure

there is no obstruction to generator extraction for

routine maintenance purposes.

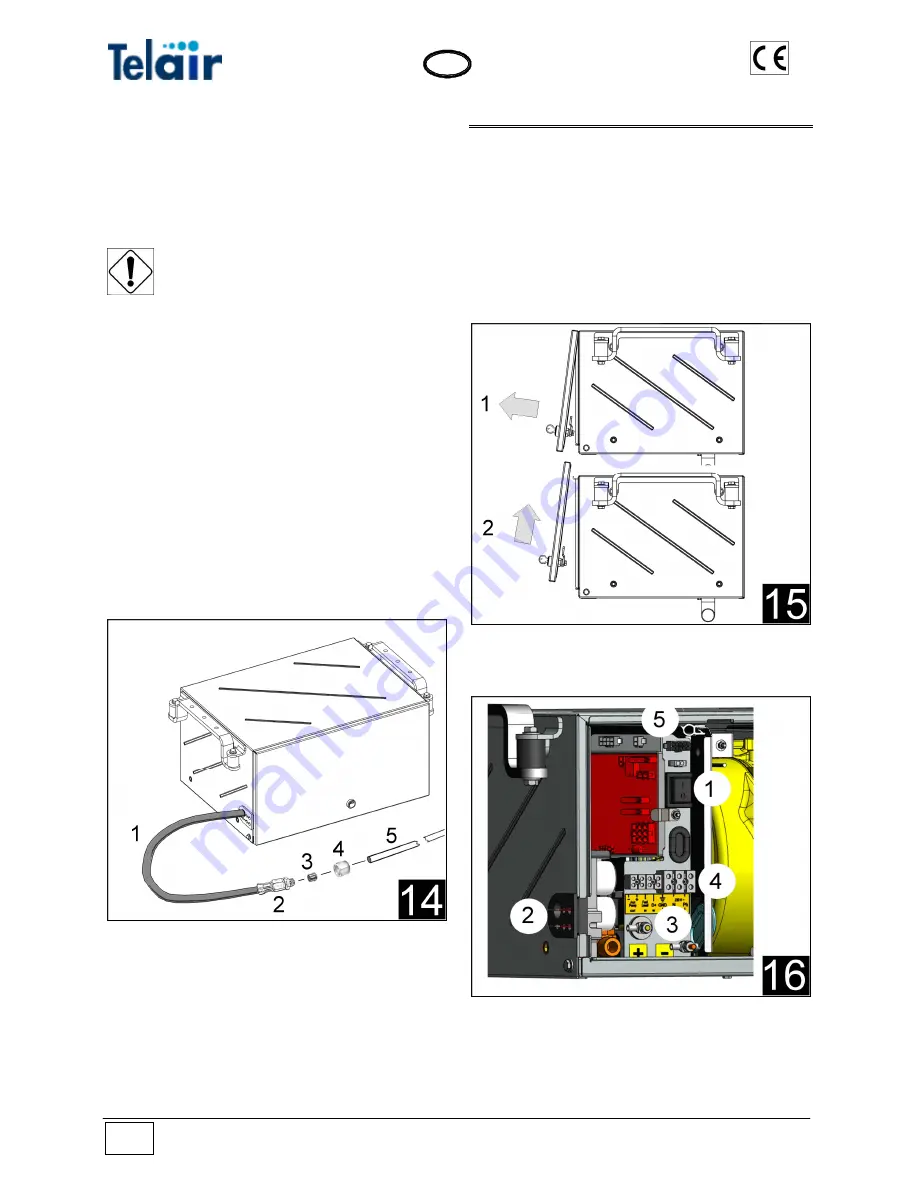

4.4 LPG hose connection

The generator must be fuelled with

LPG in a gaseous state at a pressure of 30

mb. Higher pressures can seriously damage

the generator.

The rubber hose exits from the left side of the

generator (fig. 14 ref. 1): this is used to fuel the

engine with LPG. At the end of the hose there is

a fast connector with an ogive (diameter 8 mm)

suitable for connection to the vehicle steel piping

system as shown in the figure.

Insert the nut (fig. 14 ref.4) and the ogive (fig. 14

ref. 3) in the steel pipe (fig. 14 ref. 5) coming from

the LPG system, then tighten the nut all the way

onto the connector.

If the vehicle LPG system consists of copper pip-

ing, a D6xd5 steel reinforcement bushing must

be inserted inside the hose near the ogive.

Do not crush the rubber hose or bend it too

sharply.

If the LPG tank has a fuel reserve indicator, the

service terminal strip will have a wire connector

to connect the electrical wire coming from the

fuel sensor switch.

5 ELECTRIC WIRING CONNECTIONS

5.1 Access to internal electrical connections

To carry out electrical connections to the genera-

tor it is necessary to remove the front door.

To do this release the lock, pull the lower part of

the door outwards (fig. 15 ref. 1), then push it

upwards (fig. 15 ref. 2). Store it in a safe place

until it is refitted at the end of generator connec-

tion operations.

5.2 Safety Switch

Before starting any maintenance operations or

carrying out electrical connections inside the

generator, the safety switch must be turned to its

O (Off) position (fig.16 ref. 1). The switch must

then be turned back to its I (On) position once the

Summary of Contents for TIG 3000G

Page 6: ...TIG 3000 G Vers 001 6 GB THIS PAGE HAS BEEN LEFT BLANK INTENTIONALLY ...

Page 28: ...TIG 3000 G Vers 001 28 GB 12 TIG 3000 G WIRING DIAGRAM ...

Page 29: ...Vers 001 TIG 3000 G 29 GB ...

Page 31: ...Vers 001 TIG 3000 G 31 GB 13 TIG 3000 G SPARE PARTS LIST ...

Page 32: ...TIG 3000 G Vers 001 32 GB ...

Page 33: ...Vers 001 TIG 3000 G 33 GB ...

Page 34: ...TIG 3000 G Vers 001 34 GB ...

Page 42: ...TIG 3000 G Vers 001 42 GB Notes ...

Page 43: ...Vers 001 TIG 3000 G 43 GB ...

Page 44: ......