GB

GB

36

37

PROGRAMMING THE MAINTENANCE ALARM

The SN24 control unit signals a maintenance alarm by means of 6 flashes of the internal red LEDs.

The number of cycles after which the alarm is signalled is set by default at 100,000. To modify this parameter, proceed as

follows:

1.

With the barrier down, press Prog/Stop for about 10 seconds (after three seconds LD1 illuminates; keep pressing

until LD1 goes out again)

2.

The maintenance alarm has now been deleted so it has to be reprogrammed.

3.

The number is set in multiples of 10,000. Press P/P to increase the flashes of LED LD1 (the maximum number of

flashes is 10, corresponding to 100,000 manoeuvres).

4.

Press key P3 to save the number set.

3)

The number is displayed as follows:

- First figure: number of flashes of the red and yellow LEDs together (hundreds of thousands)

- Second figure: number of flashes of the yellow LEDs added together (tens of thousands)

- Third figure: number of flashes of the red LEDs added together (thousands)

Example: display of 210,000 duty cycles.

- Red and yellow LEDs flash twice

- Pause

- Yellow LEDs flash once

- Pause

- Red LEDs do not flash

- End

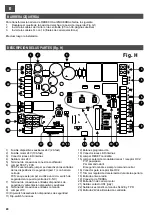

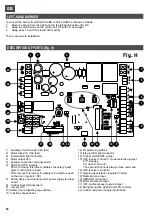

PAIR OF OPPOSITE BARRIERS, MASTER-SLAVE FUNCTION

This installation mode allows a pair of opposite barriers to be operated in synchrony.

1.

Install the two barriers, adjusting the open and closed positions if necessary.

2.

Select the main (MASTER) barrier and connect all the system functions (controls, radio receivers, safety devices,

photocells, etc.) to it.

3.

Leave all the default settings unchanged on the secondary (SLAVE) barrier. Only connect the edge, if installed.

Set the 8 dip-switches ON. Perform a reset.

4.

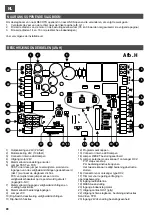

Connect the Slave output of the MASTER barrier to the “P/P” input of the SLAVE barrier, terminal “-” (5) of the MASTER to

“C” (22) of the SLAVE and terminal “D” (6) of the MASTER to P/P (19) of the SLAVE. If the connection is correct, the LED

of the “P/P” output of the SLAVE barrier will start to flash.

5.

Connect the Slave output, terminal “D” (6), of the SLAVE barrier to “PA” (20) of the MASTER barrier.

6.

Test the system, trying out the various commands and the safety devices of the two barriers.

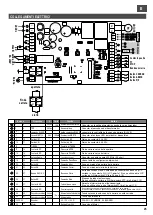

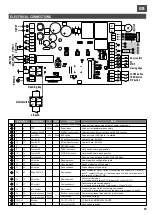

The SNAP4 barrier signals any malfunctions by flashing the red LEDs on each side of the control cabinet:

ERROR SIGNALLING

14

1

2

3

4

5

with the edge pressed or an electrical connection failure

edge contact broken

No. of flashes

Description

Meaning

rod forced

signals manual forcing with bar closed

encoder tripped

obstacle detected

encoder failure

encoder malfunction or connection error

motor control driver failure

mofset malfunction

6

7

maintenance alarm

set number of manoeuvres exceeded

electric limit switch failure or connection error

limit switch error

INITIAL PROGRAMMING AFTER control unit REPLACEMENT

This procedure is only necessary if the SN24 control unit of the SNAP4 barrier is replaced. After this operation, continue with adjustment of

the open and closed points, if necessary.

1.

Perform a reset by holding down the P3 and PROG/STOP buttons. Release the buttons when LED LD1 illuminates.

2.

Press the “P/P” button. The barrier will perform a series of movements and stop in the closed position.

3.

When LED LD1 goes out, the procedure has been completed.

TECHNICAL DATA

Motor voltage

Max. motor current

Maximum motor power

Maximum torque

Max. rod length

Max. operating angle

Operating time

Duty cycle intensity

Encoder

Electric limit switches

Lubricating grease

24

Vdc

MOTOR

U.M.

A

12

W

300

Nm

600

4250

°

mm

3-6

100

sec.

intensive

Y

Y

TS10

Model

Power supply voltage

Max. current

Electronic deceleration

Compatible with Sun Power

SN24

CONTROL UNIT

U.M.

Vac

230

A

1,5

Y

Y

Operating temperature

Degree of protection

Weight

-20 +55

°C

GENERAL DATA

U.M.

IP

54

Kg

50

DISPOSAL

This product is made up of various components that could contain pollutants. Dispose of properly!

Make enquiries concerning the recycling or disposal of the product, complying with the local laws in

force.

EC DECLARATION OF CONFORMITY

The manufacturer: Telcoma srl

via L. Manzoni, 11 - 31015 - Z.I. Campidui Conegliano (TV) - ITALY

DECLARES that the product: SNAP4

complies with the following EEC directives:

-EMC Directive 2004/108/EC

-Low Voltage Directive (LVD) 2006/95/EC

Conegliano, 17/02/2012

The Legal Representative

Ennio Ambroso

Summary of Contents for RAPPER4TL

Page 4: ...I F E GB D NL 270 Fig D min 200 mm 310 240 m in 400 227 160 min 350 Fig E1 Fig E2 4...

Page 5: ...I F E GB D NL Fig F Fig G 4 5...

Page 54: ...NOTE...

Page 55: ......