Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

2

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

1.2 Installation Guidelines

Elevated Operating Ambient

– If installed in a closed or multi-unit rack assembly, the operating ambient temperature of

the rack environment may be greater than the room ambient. Therefore, consideration should be given to installing the

equipment in an environment compatible with the maximum ambient temperature (TMA) specified by the manufacturer.

Reduced Air Flow

– Installation of the equipment in a rack should be such that the amount of air flow required for safe

operation of the equipment is not compromised.

Mechanical Loading

– Mounting of the equipment in the rack should be such that a hazardous condition is not achieved

due to uneven mechanical loading.

Circuit Overloading –

Consideration should be given to the connection of the equipment to the supply circuit and the

effect that overloading of the circuits might have on overcurrent protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Reliable Earthing

– Reliable earthing of rack-mounted equipment should be maintained. Attention should be given to

supply connections other than direct connections to the branch circuit (e.g. use of power strips).

Disconnect Device

– A readily available disconnect device shall be incorporated in the building installation wiring.

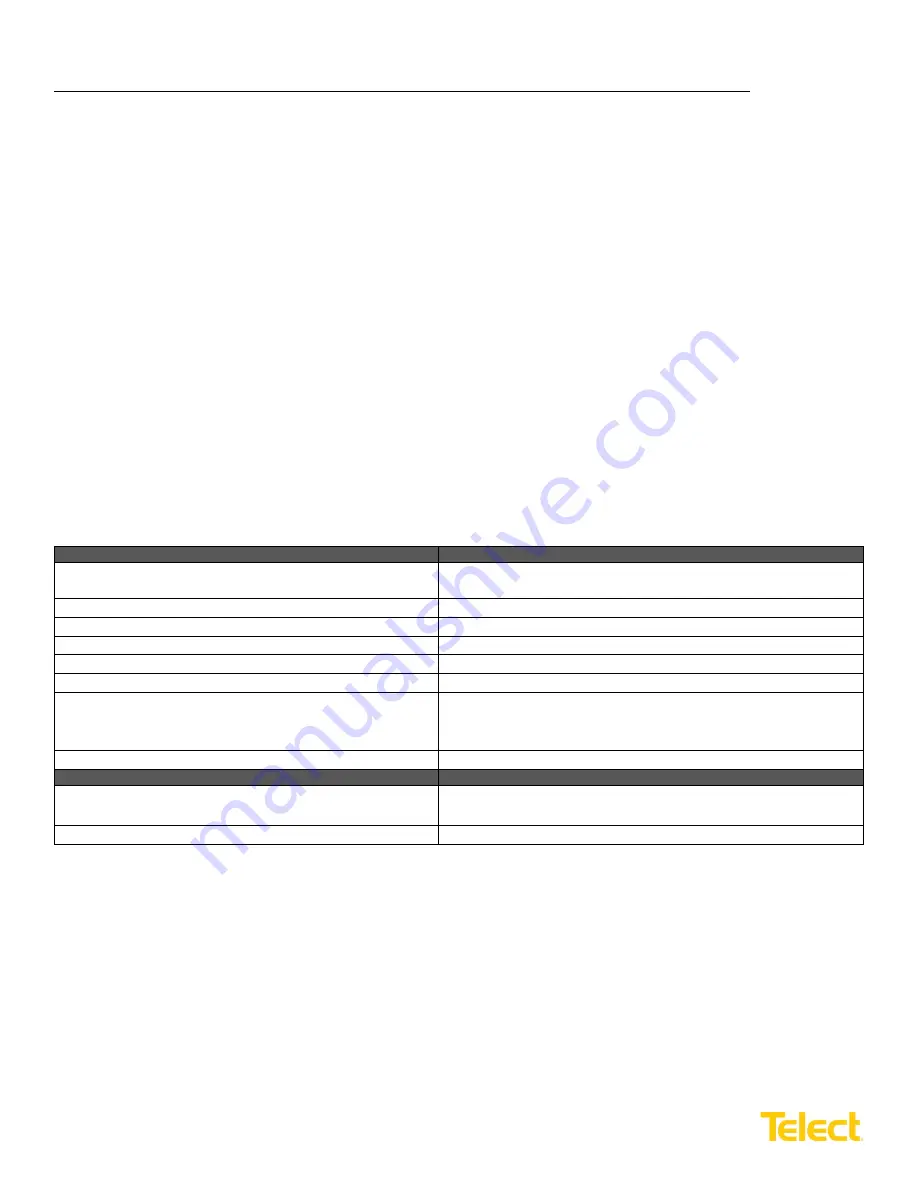

1.3 Specifications

Inputs:

Specifications:

Voltage range (nominal voltage)

±

21.6V to

±

30V (nominal ±24 VDC)

-40V to -60V (nominal -48 VDC)

Max. input load rating

600A per side at max. operating ambient of 49

°

C (120

°

F)

Short circuit withstand rating

5000A

Nominal power loss at full load

Less than 75W per side @ 28,800W full load per side (600A x 48V)

Percentage of full power dissipation at nominal voltage

Less than 1%

Max. input interrupt device

750A

Input terminal studs (with nuts, flat washers and spring

washers) for dual-hole compression lugs

Two pairs of

3

/

8

-16 studs on 1-in. centers per terminal [max. lug

width of 1.94-in. (49.2 mm)] per pair. Torque nut (using

9

/

16

-in. or 15

mm wrench) to 150-in./lb. (~17 N

•

m), max.

Input wire size

#1 AWG to 750 MCM

Grounding:

Specifications:

Earth GND terminal bolts (with washers) for dual-hole

compression lug

Two pair of

1

/

4

-20 threaded holes on

5

/

8

-in. centers. Torque bolts

(using

7

/

16

-in. or 12 mm wrench) to 50-in./lb. (5.5 N

•

m), max.

Ground wire size

#2 AWG (min.) for any input interrupt device 400A or more