Dual-Feed 600A Load Center Frame

600CB10 & 600CB12 Installation Guide

4

© Telect, Inc. All rights reserved. 7.14.17 136429-2

509.926.6000 :: www.telect.com

ALERT! Only qualified technicians may install and maintain this product. Verify all connections meet

requirements specified in local electric codes or operating company guidelines before supplying power.

Protect this equipment with a fuse or breaker sufficient to interrupt power levels specified.

Install this product in locations accessible only to qualified personnel. The panel weighs more than 35 lbs.

(~ 16 kg); two persons may be required for handling and installing the Load Center Frame.

1.4 Installation Instructions

Please read these instructions carefully before beginning installation. If assistance is required, call Technical Support at

509.926.6000 or email at

support@telect.com

.

•

Telect is not liable for shipping damage. If damaged, notify the carrier and call Telect at 509.926.6000 for

further recourse.

•

Telect recommends that you install load straps before installing the load center on the rack. Also, install load

straps now for future add-on loads.

•

Inspect equipment after unpacking and compare it to the packing list. Immediately report any shipping damage,

defects or missing parts to Telect at 509.926.6000. Keep all documentation that comes with your shipment.

1. Assign interrupter positions and install load straps for those positions before installing the load center in a rack

as follows:

a. Choose interrupter positions for breakers or fuses.

You may mix interrupter ratings and single- and multi-pole interrupters in the same load center. Telect

recommends not mixing fuses with circuit breakers.

•

Avoid mixing non-mid-trip and mid-trip breakers.

•

Avoid mixing TLS/TPS with TPC fuses. (TLS and TPS fuses are compatible but made by

different manufacturers.)

•

Do not use multiple, single-pole breakers or fuses with multi-pole load straps.

b. Record interrupter position(s) and amperage of each intended interrupter.

•

To mitigate heat buildup caused by heavy loads

≥

100A, plan a space on one side of the interrupters.

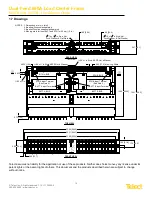

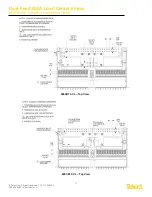

c. Remove bottom screw holding circuit breaker cover to selected interrupter positions. Refer to Figure 2.

•

Retain screw and cover if you intend to use circuit breaker

•

Retain screw but discard cover if you intend to use fuses

•

Remove corresponding screw in plastic load-strap support

•

Slip receptacle(s) of load strap into plastic load strap receptacle holder and fasten with screw removed in the

previous step