47

Teledyne API Model 480L O

3

Monitor User Manual

09419A DCN8342

7.

MAINTENANCE AND ADJUSTMENTS

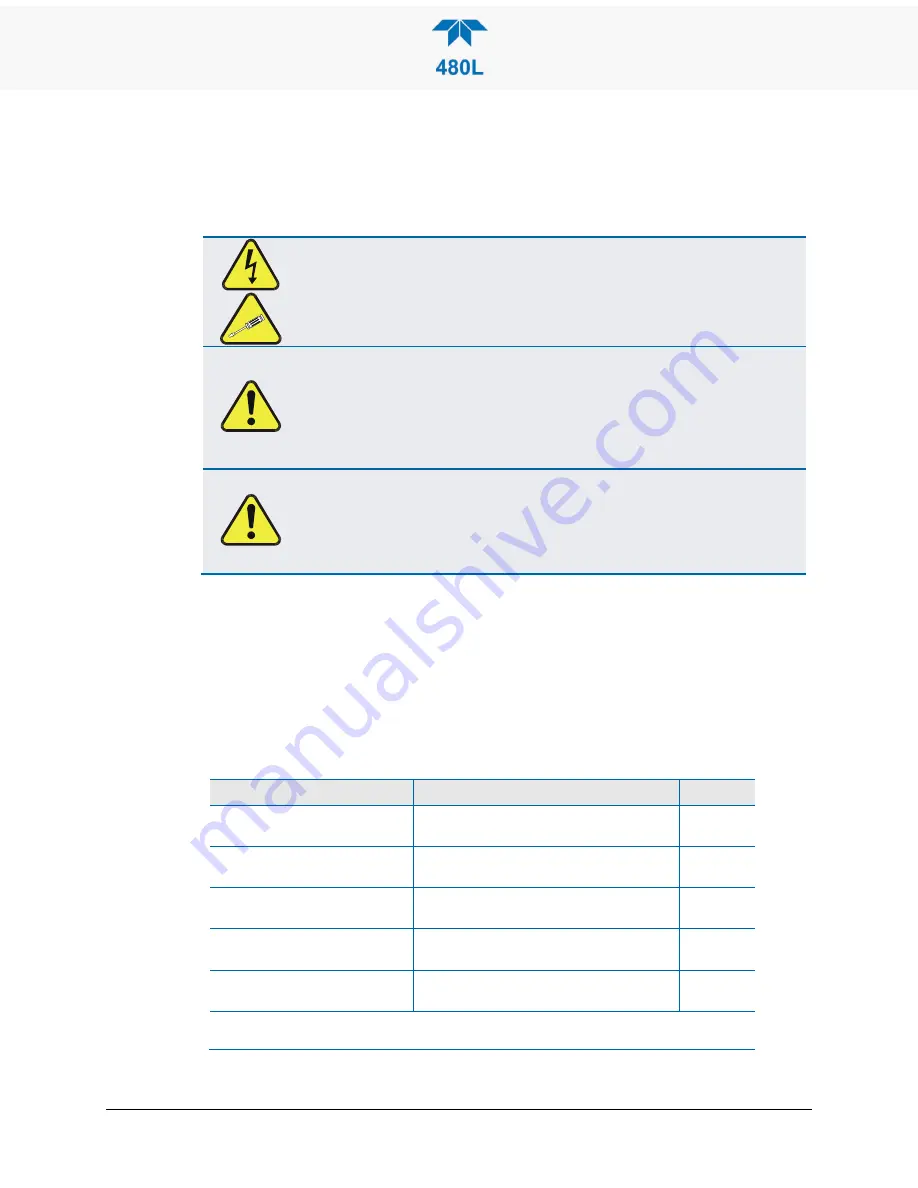

WARNING – ELECTRICAL SHOCK HAZARD

The operations outlined in this section are to be performed by

qualified maintenance personnel only!

CAUTION – RISK OF PERSONAL INJURY: HAZARDOUS GAS

Prior to opening the front panel for service of any kind, ensure first

that the area is well-ventilated before slowly opening the panel and

allowing gradual dissipation of any HAZARDOUS GAS that may

have accumulated within the enclosure.

CAUTION – RISK OF PERSONAL INJURY: UV RADIATION

Do not look at the UV LED while the unit is operating. UV light can

cause eye damage. Always use safety glasses made from UV

blocking material. (Generic plastic glasses are not adequate).

7.1 MAINTENANCE SCHEDULE

Table 7-1 below outlines the suggested maintenance procedures and intervals for

ensuring the 480L continues to operate accurately and reliably. These intervals are

based on continuous (24 hours a day – 7 days a week) operation. These intervals

may be lengthened for intermittent operation.

Table 7-1. Maintenance Schedule

Maintenance Item

Recommended Interval

Section

Replace internal particulate

filter

6 months

1

Adjust UV LED

As Indicated by UV Lamp Status or

Sensor Error messages

Replace UV LED

When adjustment can no longer be

effective.

Replace sample pump

If either the flow setpoint can’t be met

or the pump stops working.

Replace Sensor Module

Valve

2 years

1

When external sample line pre-filters are used. If pre-filters are not used, internal

sample filter should be replaced every month.

Summary of Contents for 480L

Page 2: ......