Troubleshooting and Service

Teledyne API – Model T300/T300M CO Analyzer

236

4.

SUSPECT A LEAK FIRST!

•

Technical Support data indicate that the majority of all problems are eventually

traced to leaks in the internal pneumatics of the analyzer or the diluent gas and

source gases delivery systems.

•

Check for gas flow problems such as clogged or blocked internal/external gas

lines, damaged seals, punctured gas lines, a damaged / malfunctioning pumps,

etc.

5. Follow the procedures defined in Section 11.5 to confirm that the analyzer’s vital

functions are working (power supplies, CPU, relay PCA, touchscreen, PMT cooler,

etc.).

•

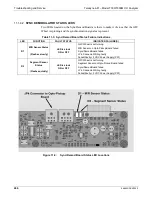

See Figure 3-6 for the general layout of components and sub-assemblies in the

analyzer.

•

See the wiring interconnect diagram and interconnect list in Appendix D.

11.1.1.

FAULT DIAGNOSIS WITH WARNING MESSAGES

The most common and/or serious instrument failures will result in a warning message

being displayed on the front panel. Table 11-1 lists warning messages, along with their

meaning and recommended corrective action.

It should be noted that if more than two or three warning messages occur at the same

time, it is often an indication that some fundamental analyzer sub-system (power supply,

relay board, motherboard) has failed rather than an indication of the specific failures

referenced by the warnings. In this case, a combined-error analysis needs to be

performed.

The analyzer will alert the user that a Warning message is active by flashing the FAULT

LED, displaying the the Warning message in the Param field along with the

CLR

button

(press to clear Warning message). The

MSG

button displays if there is more than one

warning in queue or if you are in the TEST menu and have not yet cleared the message.

The following display/touchscreen examples provide an illustration of each:

06864D DCN7562

Summary of Contents for T300

Page 2: ......

Page 182: ...06864D DCN7562 ...

Page 227: ...225 This page intentionally left blank 06864D DCN7562 ...

Page 228: ...06864D DCN7562 ...