GD10-P00 and GD10-PE0

INFRARED POINT GAS DETECTOR

OPERATING MANUAL

22

850-811250

Revision 13b

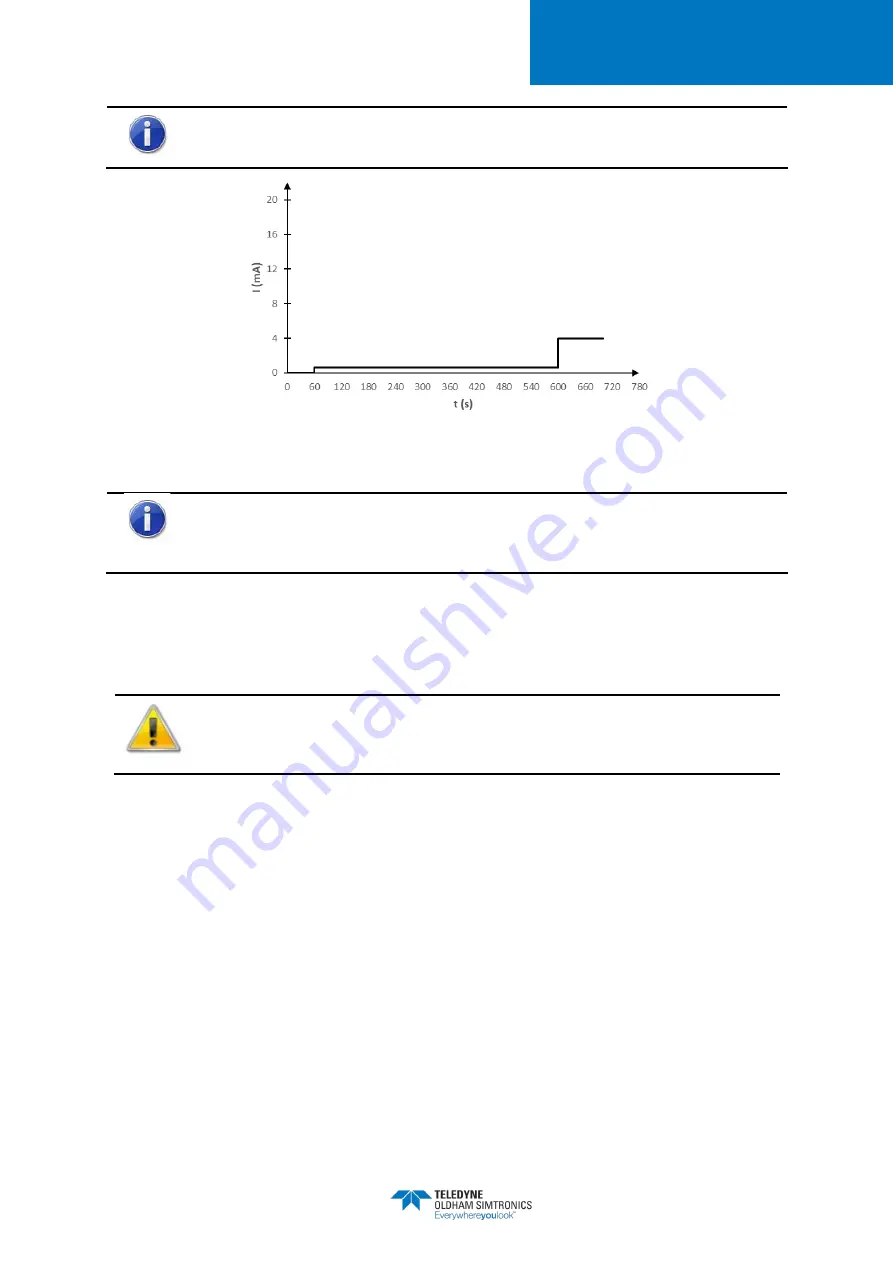

Figure 12: Analog output during specific startup conditions

5.3

Checking system functions

Full specification obtained after 30 min. warmup time

The GD10P is factory calibrated and does not require any adjustments before operation. A check

prior to putting into service should however consist of:

1) Clean the optical surfaces.

The detector may have been collecting dirt after being initially installed. It is thus crucial to

clean the optical parts before testing the detector (refer to Paragraph 7.1 “Cleaning of

optical lens/mirror”).

2) Do a gas test.

To make sure the detector works fine you should as a minimum do a function check as

described in paragraph 7.2 “Function test”.

Optionally you may do a full calibration test as described in paragraph 7.3 “Calibration

test”.

Startup period can be up to 10 minutes under very specific conditions. This

corresponds to the temperature adjustment time of the different components.

If the analog output of the detector stays at 0.6mA after 10 minutes then the detector

could have a zero drift issue. This issue can be solved by applying a “Re-Zero” to

the detector. This procedure is described in section 7.4.

Summary of Contents for Everywhereyoulook GD10-P00

Page 1: ...850 811250 Revision 13b GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL...

Page 10: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 4 850 811250 Revision 13b...

Page 14: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 8 850 811250 Revision 13b...

Page 18: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 12 850 811250 Revision 13b...

Page 46: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 40 850 811250 Revision 13b...

Page 47: ...GD10P00 and GD10PE INFRARED POINT GAS DETECTOR OPERATING MANUAL 850 811250 Revision 13b 41...

Page 48: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 42 850 811250 Revision 13b...

Page 52: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 46 850 811250 Revision 13b...

Page 56: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 50 850 811250 Revision 13b...

Page 57: ...GD10P00 and GD10PE INFRARED POINT GAS DETECTOR OPERATING MANUAL 850 811250 Revision 13b 51...

Page 58: ...GD10 P00 and GD10 PE0 INFRARED POINT GAS DETECTOR OPERATING MANUAL 52 850 811250 Revision 13b...

Page 59: ...GD10P00 and GD10PE INFRARED POINT GAS DETECTOR OPERATING MANUAL 850 811250 Revision 13b 53...