2 Installation

Model 7300A

2-12

Teledyne Analytical Instruments

2.5

Testing the System

Before plugging the instrument into the power source:

•

Check the integrity and accuracy of the fluid connections. Make

sure there are no leaks.

•

Check the integrity and accuracy of the electrical connections.

Make sure there are no exposed conductors

•

Check that sample pressure is controlled accuracately and is

maintained between 5 to 10 psig, according to the requirements

of your process.

NOTE: Special designed systems may require checks under vacuum

or high pressure (consult manual addendum).

Power up the system, and test it by performing the following

operations:

1. Repeat the Self-Diagnostic Test, section 5.2

2.6

Calibration

2.6.1 Calibration Fluids

Zero fluids must be made by the chemistry lab or certified zero and span

gas bought from a gas supplier. The zero fluid must be the major component of

the sample, free from the component of interest.

Note: In Non-purity applications, the reference cell may be sealed

with clean air (consult factory).

The span fluid must be the major component of the sample mixed with

a small amount of the component of interest. The concentration must be 80 to

95% of the full scale range or the widest range of the instrument (if the instrument

provides more than one range).

2.6.2 Calibration

Refer to Section 4.4 of the manual to determine how to manipulate the

mode setting. The recommended calibration method is as follows:

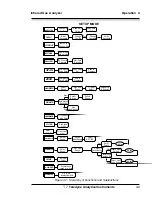

Method:

Summary of Contents for 7300A

Page 4: ...iv Model 7300A Teledyne Analytical Instruments ...

Page 12: ...1 4 1 Introduction Model 7300A Teledyne Analytical Instruments ...

Page 26: ...2 Installation Model 7300A 2 14 Teledyne Analytical Instruments ...

Page 36: ...3 Start up and Theory of Operation Model 7300A 3 10 Teledyne Analytical Instruments ...

Page 80: ...5 Maintenance Model 7300A 5 10 Teledyne Analytical Instruments ...